Vacuum Casting Services

Get fast, cost-effective, high-quality rigid parts in just days. Ideal for prototyping and small batches, urethane casting can produce parts from a few to hundreds, using materials that closely resemble production-grade plastics.

- Instant quotes & DFM feedback

- Production grade quality

- Global delivery in 7 days or less

Start a New Vacuum Casting Quote

- All uploads are secure and confidential.

10+

Material Types

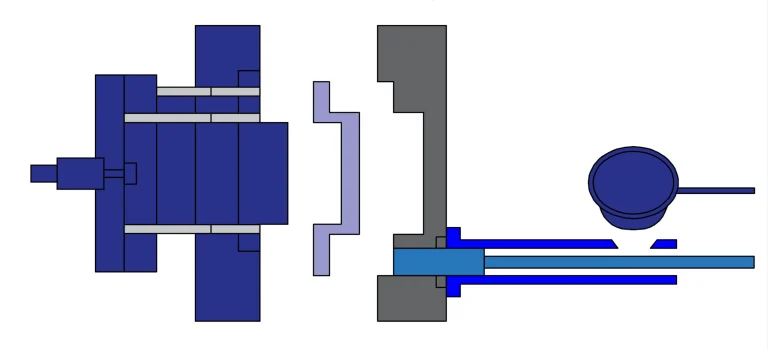

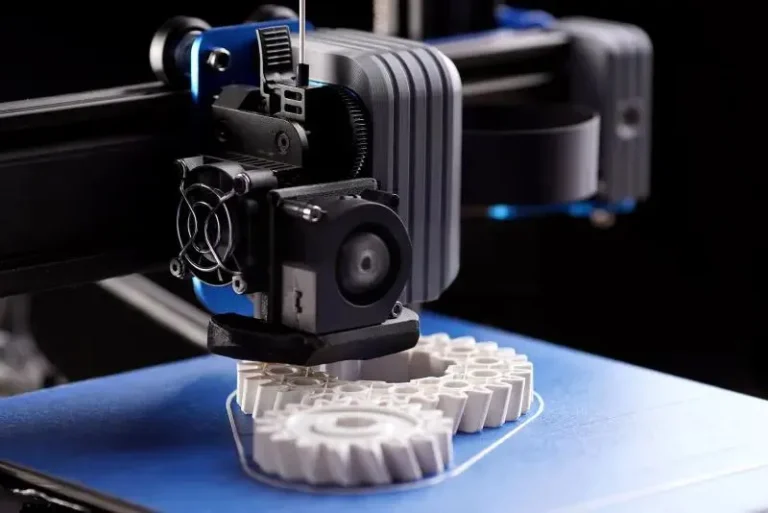

Our Vacuum Casting Process

Our Factory for Urethane Casting Services

Why Choose Us

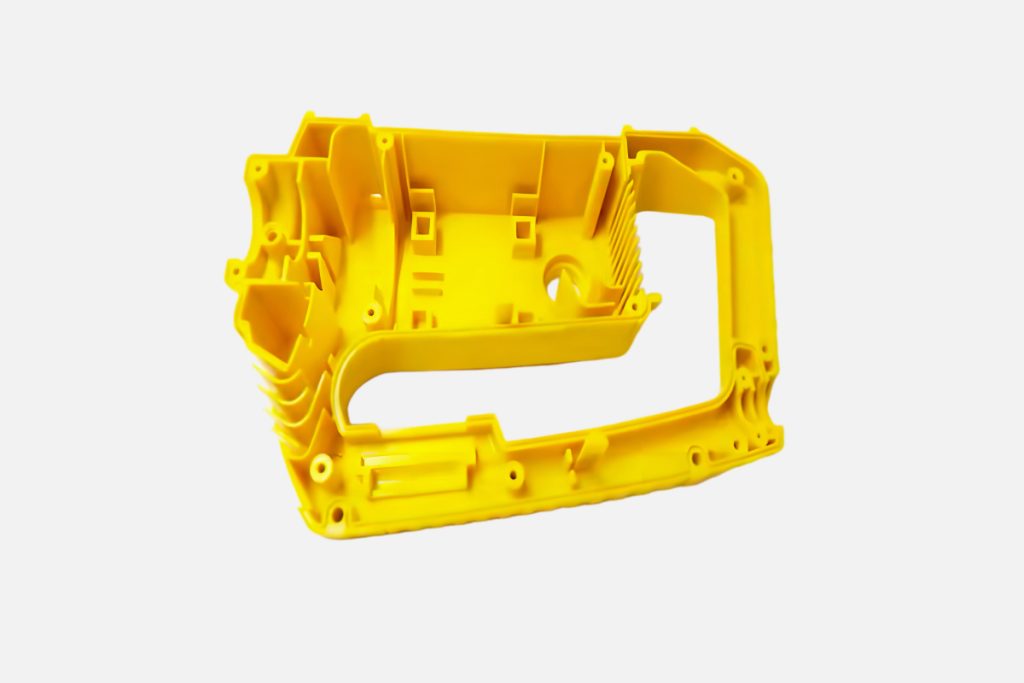

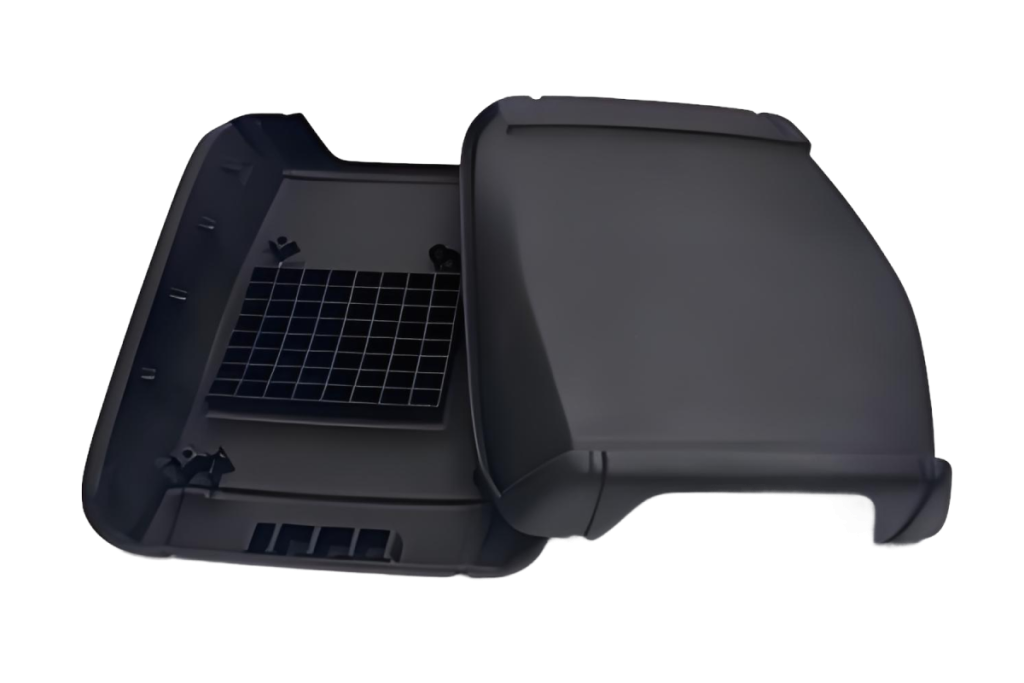

Production Quality at Low Volumes

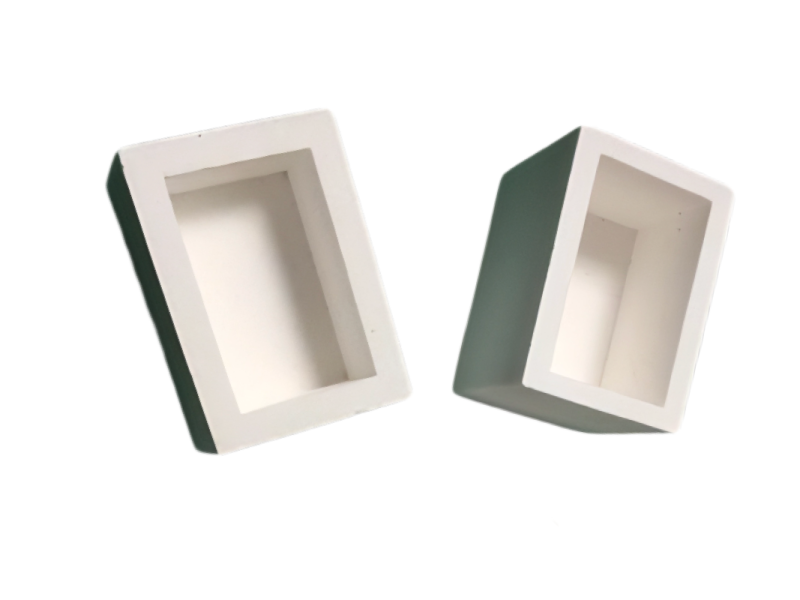

This method provides a quick and affordable way to produce 10-200 units at production-grade quality, with each silicone mold generally producing up to 20 castings.

Complex Elastomeric Parts

Urethane casting is perfect for prototyping flexible components like intricate gaskets and overmolds on rigid parts.

High Level of Detail

Urethane casting enables the creation of highly complex designs, including sharp internal corners that CNC machining can't achieve, and parts with no draft or uniform wall thickness.

Start Your Vacuum Casting Project Today!

Need high-quality prototypes or low-volume production? Contact us now for fast, precise, and durable parts!

Our CNC Machining Capabilities

Vacuum Casting Materials

Soft-rubber-like

Materials in this category offer excellent flexibility, resilience, and a rubber-like feel.

They are ideal for applications requiring cushioning, vibration dampening, or soft-touch surfaces.

Silver White

| Color: | Black, Gray, White, Transparent, Dark Blue |

| Subtypes : | PU8150, PU8400 |

PA-like

PA-like materials mimic the properties of nylon, offering good strength, wear resistance, and flexibility.

These are commonly used for durable parts that need to withstand friction and abrasion.

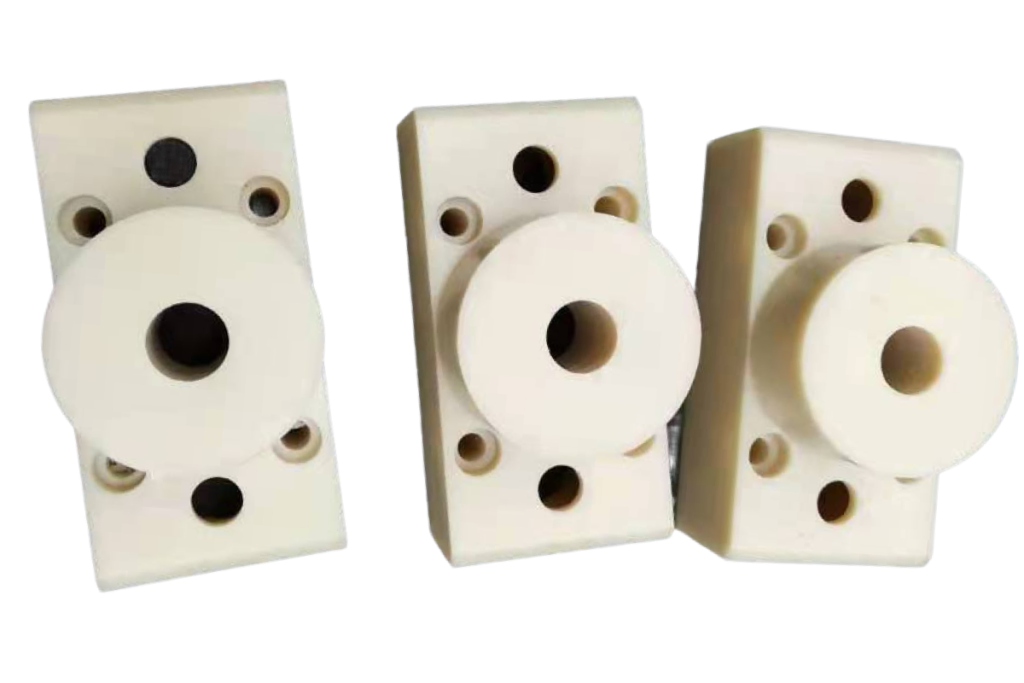

ABS-like

ABS-like materials provide a balance of toughness, impact resistance, and ease of processing.

They are widely used for parts that need strength, durability, and a smooth finish, such as in automotive or consumer electronics.

PMMA-like

PMMA-like materials are clear, with excellent optical clarity and weather resistance.

They are ideal for transparent applications where high light transmission is needed, such as lighting covers or display cases.

PP-like

PP-like materials offer good chemical resistance and are lightweight with a flexible yet rigid structure.

They are often used for packaging, automotive components, and products that require resistance to wear and chemicals.

PC-like

PC-like materials are known for their high impact resistance, transparency, and heat tolerance.

These materials are commonly used in applications requiring high strength and clarity, such as in optical components or protective covers.

Various Surface Finishes Available

At Future Parts, we provide a variety of surface finishes to enhance both functionality and aesthetics. Whether you need anodizing.

plating, or painting, we ensure your parts meet your precise specifications.

| Name | Colors | Applicable Materials | Description |

|---|---|---|---|

| Standard(As Milled) | N/a | Metal Plastics | Lorem ipsum dolor sit amet, consectetur adipiscing elit. Aenean euismod Lorem ipsum dolo |

| Standard(As Milled) | N/a | Metal Plastics | Lorem ipsum dolor sit amet, consectetur adipiscing elit. Aenean euismod Lorem ipsum dolo |

| Standard(As Milled) | Metal Plastics | N/a | Lorem ipsum dolor sit amet, consectetur adipiscing elit. Aenean euismod Lorem ipsum dolo |

Work with Our Custom Vacuum Casting Services

Initial Inquiry

We receive customer inquiries through email or other channels to understand their needs.

Requirement Assessment

We carefully review the customer’s requirements, including product specifications, quantities, and any special needs.

Quotation Delivery

Based on the assessment, we provide the customer with a detailed, accurate quotation.

Order Confirmation

Once the quotation is accepted, we finalize the order details, sign the contract, and begin the production process.

Vacuum Casting Capabilities

| Accuracy | Achieve maximum precision with tolerances as tight as ±0.15 mm. | |

| Maximum Part Size | Unlimited | |

| Minimum Wall Thickness | 1.5 mm to 2.5 mm | |

| Quantitites | 20 to 25 units per mold. | |

| Color and Finishing | Custom colors and textures are available. | |

| Typical Lead Time | Up to 20 parts delivered in 15 days or less. |

Put Your Parts into Production Today

All information and uploads will be kept confidential.

FAQs about Vacuum Casting Services

Lead times can range from 5 to 15 business days, depending on the complexity and quantity of parts required. First samples (T1) are typically ready within 5-7 days.

Vacuum casting offers quicker turnaround times, lower tooling costs, and is ideal for low-volume production, making it a cost-effective choice for prototyping and small-batch production.

Vacuum casting can achieve high precision with tolerances as tight as ± 0.1 mm, making it ideal for prototypes and parts that require detailed features.

Vacuum casting is ideal for producing small to medium quantities, typically between 10 to 500 parts, depending on the material and complexity.

Yes, vacuum casting can produce parts with a smooth surface finish and a variety of textures and colors, making them very similar in appearance to final production parts.

Resources