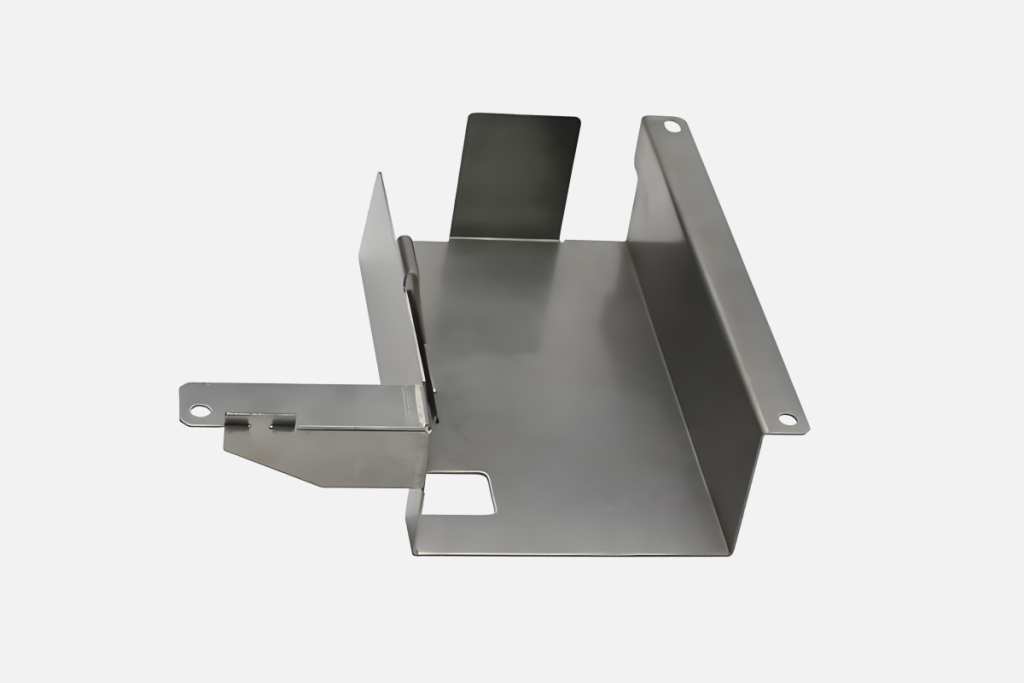

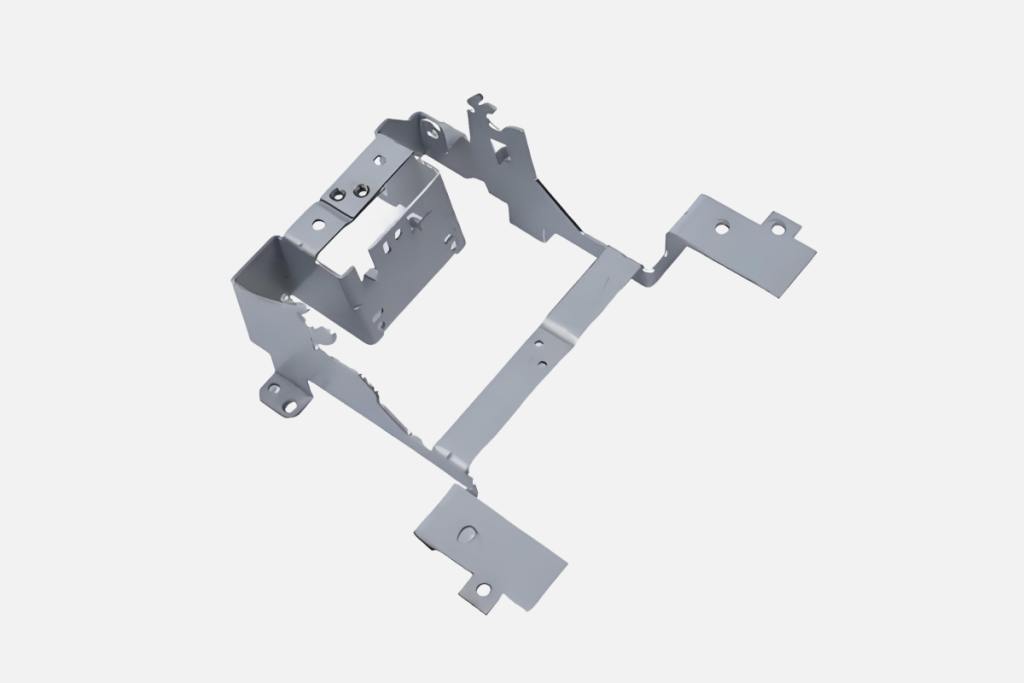

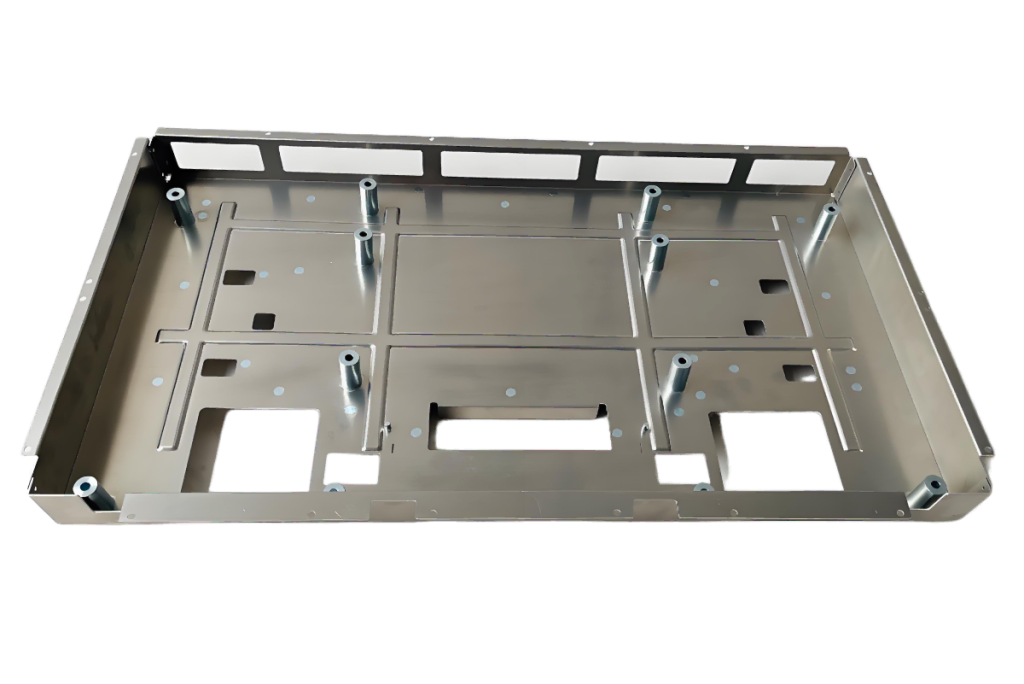

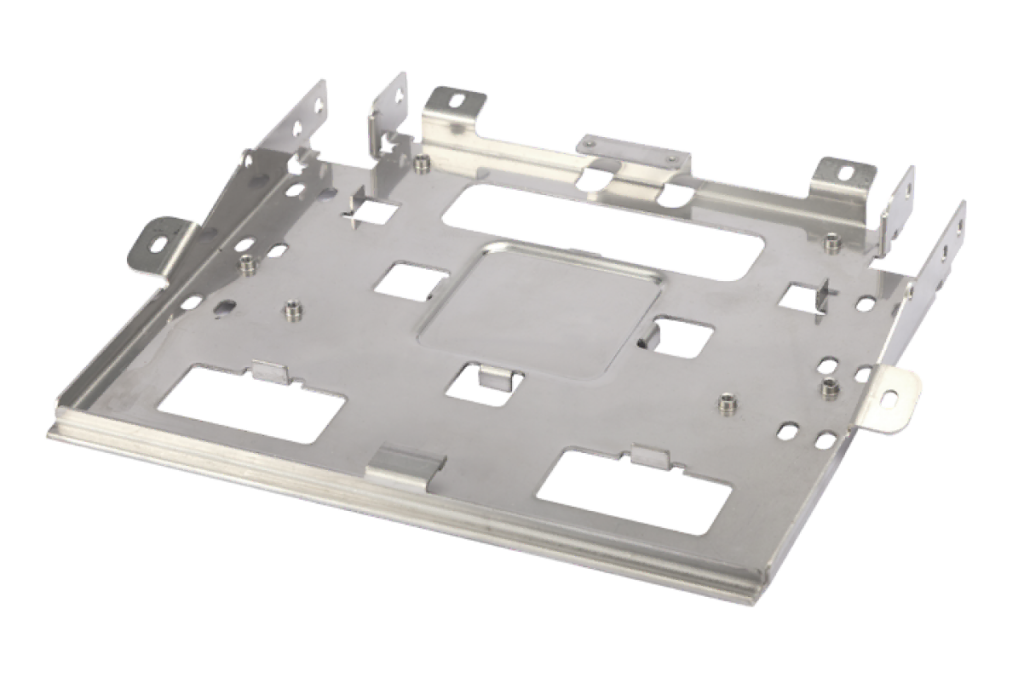

Sheet Metal Fabrication Services

Get reliable and durable sheet metal parts for both low-volume and mass production, with lead times as quick as 1 day. Choose from a wide selection of certified materials and finishing options.

- Precision: Tolerances as tight as ± 0.004" (0.1 mm)

- Fast turnaround: As fast as 1–3 business days

- Customizable materials: 20+ metals, 10+ finish options

Start a New Sheet Metal Fabrication Quote

- All uploads are secure and confidential.

ISO

9001,14001 Certified

Our Sheet Metal Fabrication Capabilities

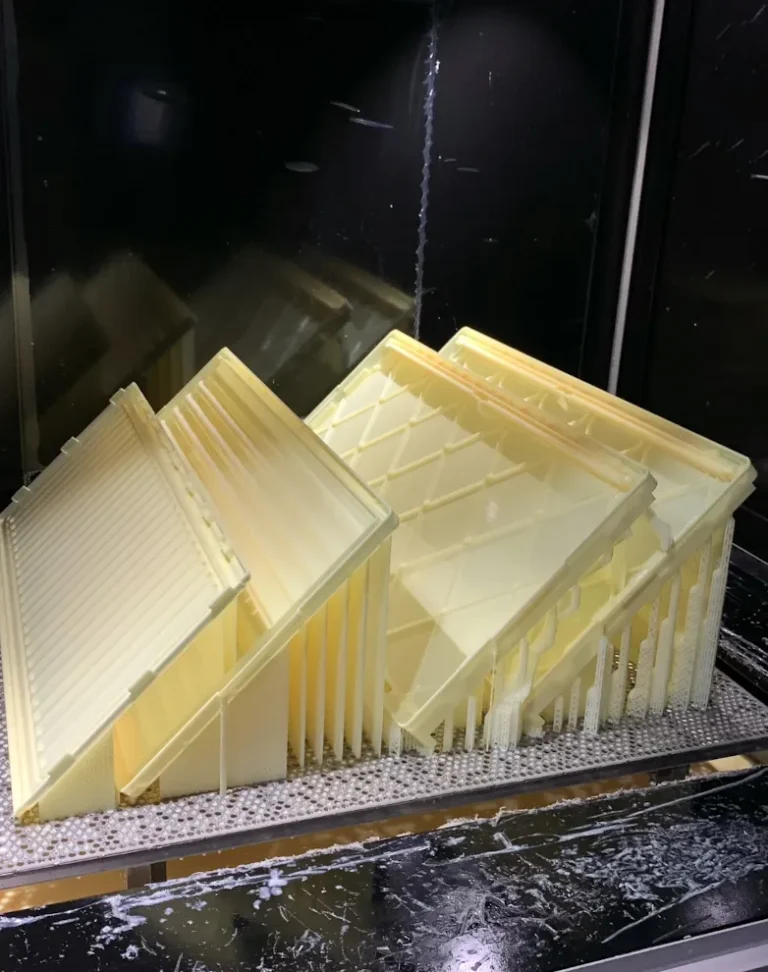

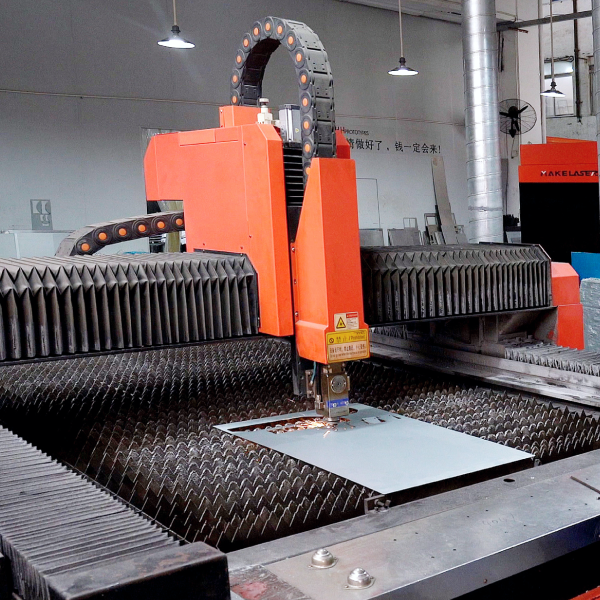

Our Factory

Why Choose Our Sheet Metal Fabrication Services

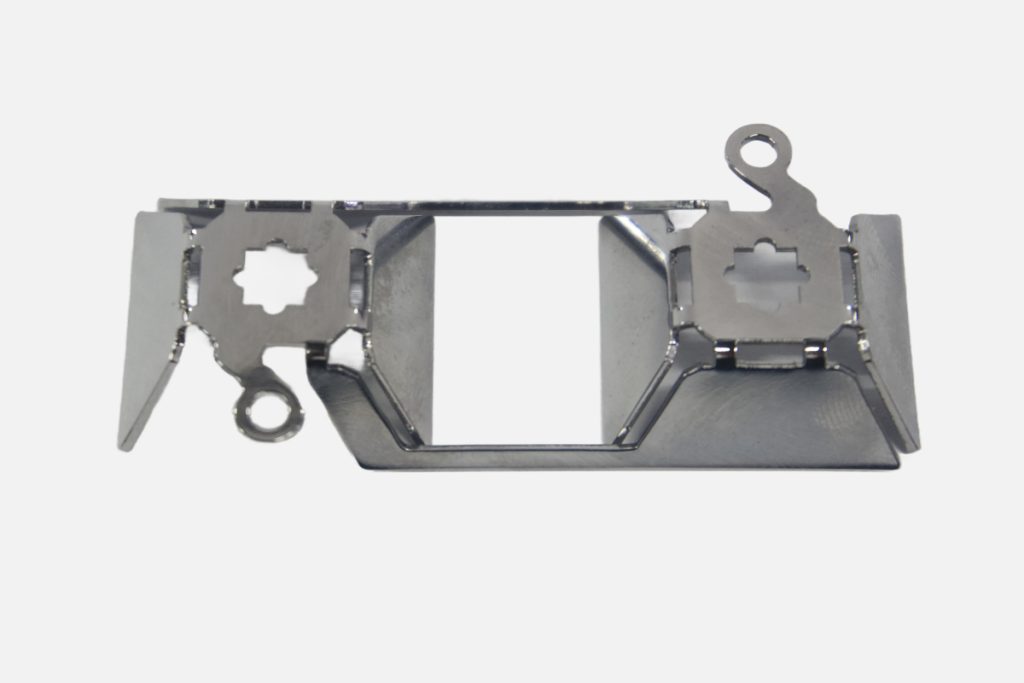

Quality Metal Parts

We follow strict industry standards, like ISO 2768-c, to ensure precision and quality in every sheet metal part we manufacture.

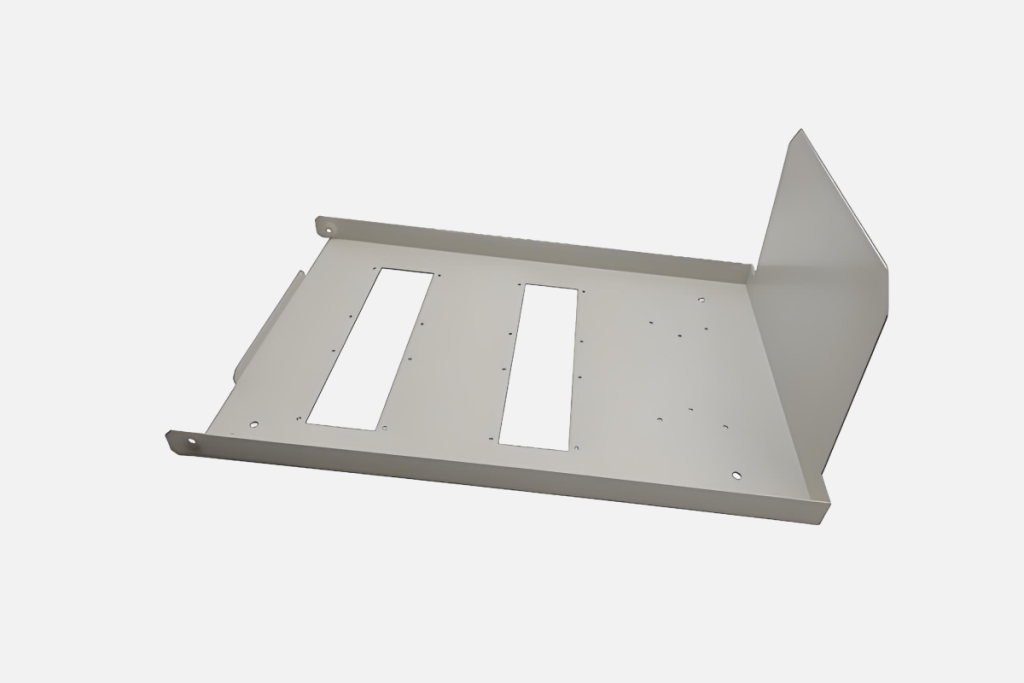

Small and Large-Volume Production

Our skilled technicians handle a wide range of materials and complex designs, offering tailored solutions for both prototypes and large-scale production.

Fast Lead Time

With automated laser cutting and bending facilities, we deliver efficient sheet metal fabrication services that bring your projects to life quickly, without compromising on quality.

Start Your Sheet Metal Project Today

Get precision, speed, and quality for your custom sheet metal parts—request a free quote now!

How Does Future Parts Sheet Metal Fabrication Work

Our Process for Sheet Metal Fabrication

Sheet Metal Fabrication Materials

Copper

Copper is an excellent material for sheet metal fabrication. It is malleable, ductile, and an extremely good conductor of both heat and electricity. It is commonly used for electrical equipment such as wiring and motors.

Red Copper

| Color: | Red Copper, Brass |

| Surface: | Pinkish orange, reddish brown, reddish-gold |

| Build Time: | 3 to 5 Business Days |

| Subtypes : | Copper C101(T2) |

| Copper C103(T1) | |

| Copper C103(TU2) | |

| Copper C110(TU0) |

Aluminum

Aluminum sheet metal offers an excellent strength-to-weight ratio and corrosion resistance, making it a popular choice in industries such as aerospace, automotive, and consumer electronics.

Yellow

Purple

| Color: | Silvery White |

| Surface: | Silvery |

| Build Time: | 3 to 5 Business Days |

| Subtypes : | Aluminum 5052 |

| Aluminum 5083 | |

| Aluminum 3003 | |

| Aluminum 3004 | |

| Aluminum 5754 |

Steel

At Future Parts, we can fabricate various grades of steel. For projects with a low budget, mild carbon steel is often the best choice due to its affordability and versatility.

Silver

| Color: | Silver |

| Surface: | Pinkish orange, reddish brown, reddish-gold |

| Build Time: | 3 to 5 Business Days |

| Subtypes : | AlSl 1020 (20#steel), SECC (Electro-galvanized steel), 1018, Q235, Q345, Galvanized Steel |

Stainless Steel

Stainless steel sheet cut to size is strong and highly resistant to corrosion and rust, making it ideal for parts that are exposed to various elements for long periods and do not easily break.

Silver

| Color: | Silver |

| Surface: | Pinkish orange, reddish brown, reddish-gold |

| Build Time: | 3 to 5 Business Days |

| Subtypes : | SS304, SS301, SS316 |

Cold Rolled Steel(CRS)

At Future Parts, we specialize in fabricating cold-rolled steel sheets. Cold-rolled steel (CRS) is produced by further strengthening hot-rolled steel through cooling at room temperature and annealing. This process results in steel with tighter dimensional tolerances and a broader range of surface finishes compared to hot rolling.

Silver

| Color: | Gray |

| Surface: | Matte or slightly glossy |

| Build Time: | 3 to 5 Business Day |

| Subtypes : | SPCC |

Various Surface Finishes Available

From anodizing and plating to painting and powder coating, we ensure that each part is treated to your exact requirements, delivering a durable, high-quality finish that meets your specifications.

| Name | Colors | Applicable Materials | Description |

|---|---|---|---|

| As Machined | N/a | Metals, plastics | Standard finish, surface roughness of 3.2 μm (126 μin), removes sharp edges and deburs parts cleanly. |

| Sand Blasting | Matte Gray | Metals, plastics | Powerfully propels blast media against surfaces to remove coatings and impurities. |

| Tumbling | N/a | Metals | Utilizes barrel or vibratory processes with abrasives to smooth and polish the surface of parts. |

| Alodine | Golden yellow, transparent | Aluminum, Aerospace Alloys | Chemical treatment process providing corrosion protection and surface preparation for paint adhesion. |

| Anodizing | Clear, black, custom | Aluminum | Electrochemical process that forms a durable, corrosion-resistant oxide layer on the surface of metals. |

| Teflon Coating | Dull, matte black, or costom | Metals, Plastics | Applies a protective layer of PTFE to reduce friction and enhance corrosion resistance. |

| Black Oxidize | Black | Steel, Iron | Chemical bath that creates a black oxide coating on metal to improve corrosion resistance. |

| Electroplating | Silver, gold, nickel | Metals | Uses electric current to reduce dissolved metal cations to form a coherent metal coating. |

| Painting | Black, white, silver, or custom colors | Metals, Plastics, Wood | Application of paint for aesthetic improvements and protective coatings. |

| Passivation | N/a | Stainless Steel, Other Corrosion-resistant Alloys | Chemical treatment to enhance the corrosion resistance of metals by removing free iron from the surface. |

| Powder Coating | Custom colors | Metals, Some Plastics | Dry finishing process using powdered paint to provide a high-quality, durable finish. |

| Electrophoresis | Black or dark grey | Metals, Ceramics | Coating process using charged particles suspended in a solvent, typically for uniform finishes. |

| Brushed Finish | Metallic | Metals | Mechanical polishing that produces a unidirectional satin finish. |

Work with Our Sheet Metal Fabrication Services Today

Partner with us for reliable, high-quality sheet metal fabrication solutions tailored to your needs!

Manufacturing Capabilities

Unless we have agreed on other tolerances in your quote, we will work to achieve and maintain the tolerances noted below, which may vary depending on the primary manufacturing method you select. (e.g., round hole 10 mm, tolerance 0.2 mm)

| Description | |

|---|---|

| General Tolerances | Metals : ISO 9023-2 |

| Cutting Feature | ± .00787'' 0.2 mm |

| Bend Angle | ± 1.0° |

| Bend to Edge | ± 0.010" 0.254 mm |

| Bend to Hole | ± 0.2 mm |

Put Your Parts into Production Today

All information and uploads will be kept confidential.

FAQs about Sheet Metal Fabrication Services

Advantages include durability, cost-effectiveness, versatility, and the ability to produce high-strength parts with precise dimensions.

Industries that benefit from sheet metal fabrication include automotive, aerospace, medical devices, consumer electronics, architecture, and industrial equipment.

The cost of sheet metal fabrication is calculated based on factors such as material type, thickness, size, design complexity, labor, surface finish, and total quantity of parts. Additional costs may also include tooling and transportation.

The delivery time is between 1 to 10 business days, depending on the complexity and quantity of the order.

We adhere to strict quality standards, including ISO 9001 and ISO 2768, and use advanced inspection tools to verify accuracy.

Resources