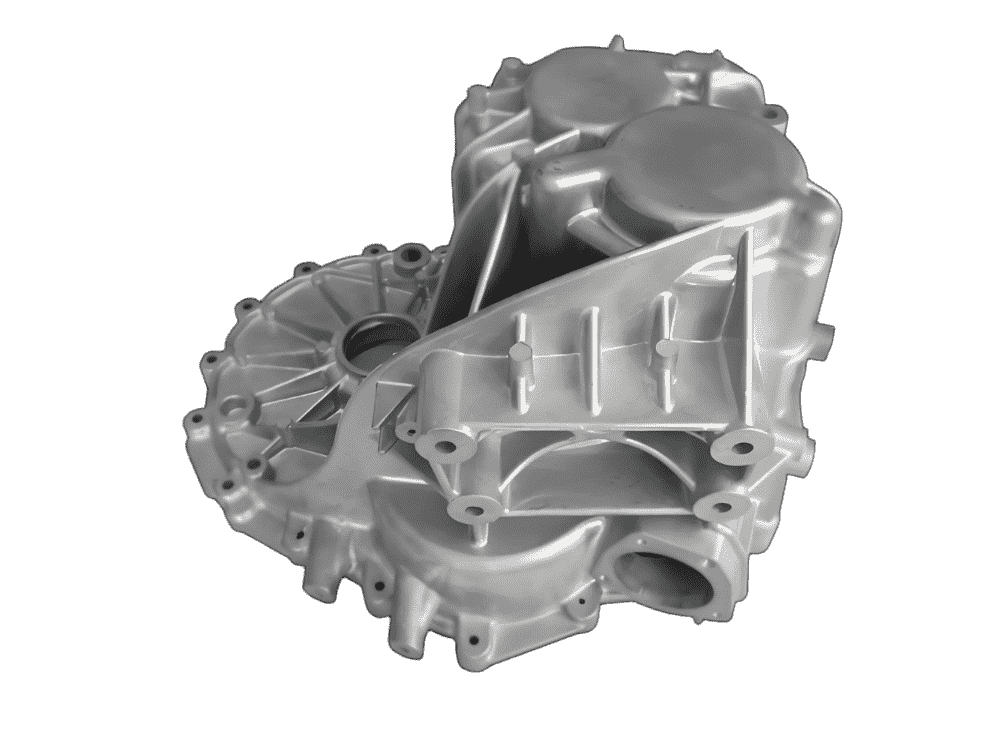

Die Casting Services

Get instant quotes for die casting, whether for prototypes or mass production. Enjoy consistent quality of metal parts with fast lead times, as quick as 10 days.

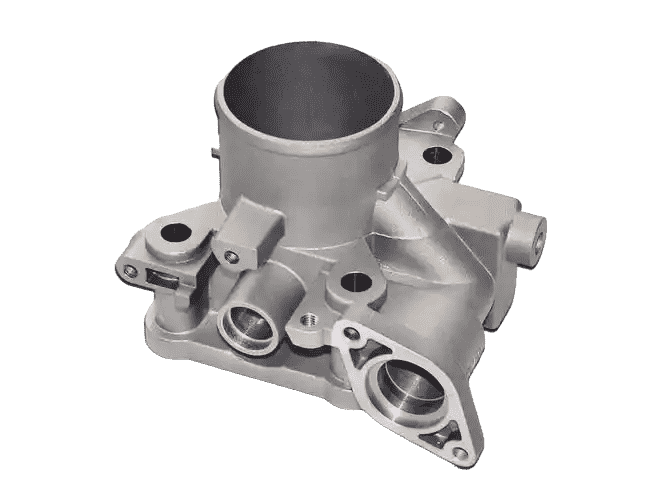

- Excellent dimensional accuracy and repeatability

- 17+ Smooth surface finishes

- Complex geometries & designs

Start a New Die Casting Quote

- All uploads are secure and confidential.

≥ 5 Days

Lead Time

Our Die Casting Capabilities

Die Casting Materials

Why Choose Us

High Quality Parts

Future Parts ensures exceptional dimensional accuracy and repeatable quality, ideal for producing intricate, complex components in high volumes.

Impactful Die Casting Solutions

We provide tailored die casting solutions with a wide range of metal alloys, ensuring optimal performance, durability, and cost-effectiveness for your specific application needs.

Fast Lead Time

With advanced die-casting technology and a streamlined production process, we deliver high-quality parts quickly and at competitive prices.

Get Your Die-Cast Parts Today!

Contact us now to produce high-quality, durable parts with fast turnaround and precise finishes.

How to Work with Us for Die Casting

Get in touch with our team to discuss your project, and we’ll guide you through the entire die casting process, from design to production.

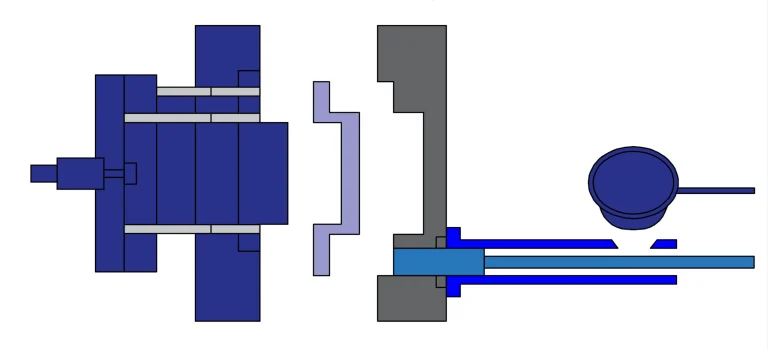

Die Casting Capabilities

| Description | ||

|---|---|---|

| Minimum Part Weight | 0.017 kg | |

| Maximum Part Weight | 12 kg | |

| Minimum Part Size | ∅17 mm × 4 mm | |

| Maximum Part Size | 300 mm × 650 mm | |

| Minimum Wall Thickness | 0.8 mm | |

| Maximum Wall Thickness | 12.7 mm | |

| Quality Control | ISO 9001 Certified | |

| Minimum Possible Batch | 1000 pcs |

Put Your Parts into Production Today

All information and uploads will be kept confidential.

FAQs on Die Casting Services

Die casting provides high accuracy, fast production cycles, and the ability to create complex shapes with excellent surface finishes.

Lead time typically ranges from 30 to 40 business days, depending on part complexity and order volume.

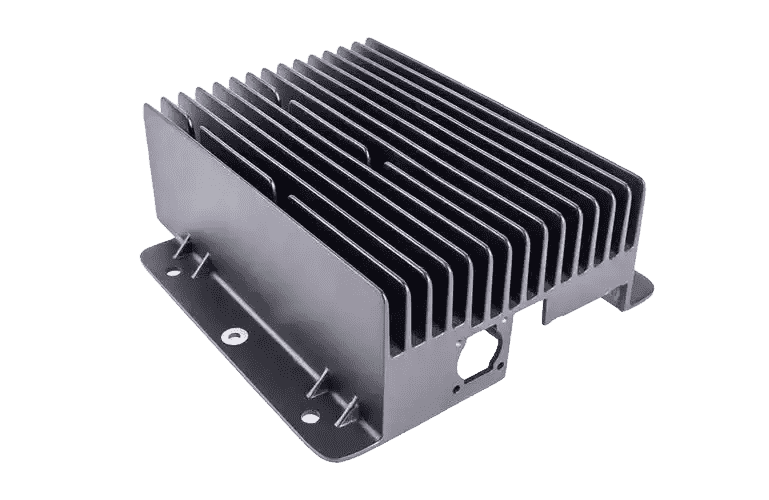

Die casting is commonly used in industries like automotive, aerospace, electronics, and consumer goods for parts like housings, connectors, and structural components.

Shot life can range from 10 w to 30 w+ shots, depending on the material used and part complexity.

We use stringent quality control processes, including visual inspections, dimensional checks, and material testing to ensure parts meet specifications.

Resources