Walk into any machine shop, and you’ll see CNC machines turning chunks of metal into exactly-shaped parts, cut just right. It’s pretty amazing to watch. Think about all the stuff in stores, from the parts in your car to the bits inside your phone.

While CNC programming plays a crucial role in design, it’s precision machining services like those offered by Future Parts that turn those designs into real, high-quality parts. For folks who want to learn how it all works or get better at running these machines, getting the basics down is where it starts. So, stick around, because we’ll walk through the whole thing together.

What is CNC Programming?

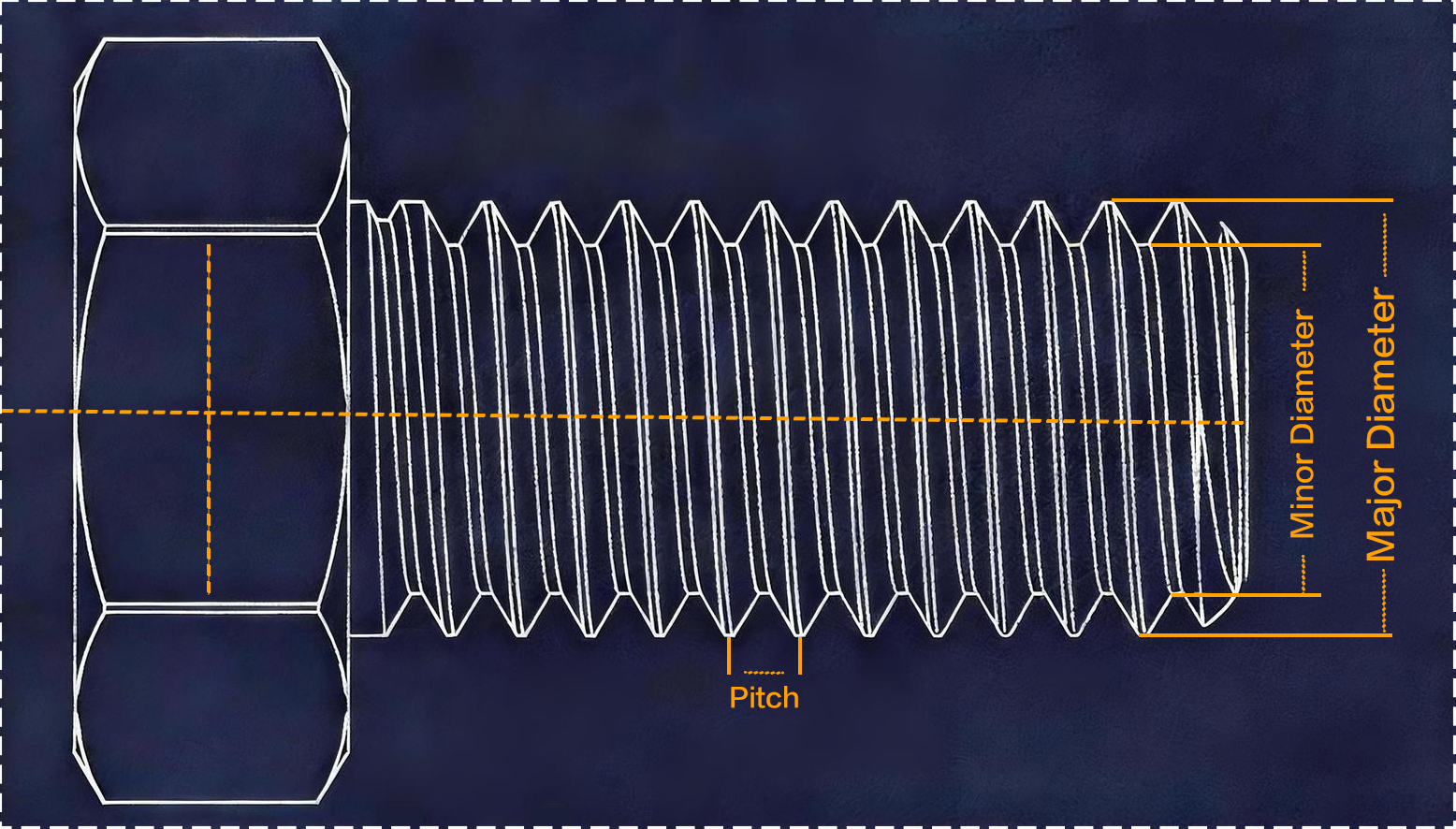

A CNC program tells machines how to cut, shape, and assemble parts with extreme precision. Instead of manual methods, CNC machines follow coded instructions to ensure every piece meets exact specifications using G-code for speed, depth, and movement.

You can set up a CNC machine in a number of different ways. CAM software takes over the process, while manual code gives you full control. When cutting by hand, mistakes can happen, but CNC machines always make the same results, whether they’re making one sample or thousands.

To make your plans come to life accurately, you must first learn these important CNC programming codes.

Essential CNC Programming Codes You Need to Know

CNC machines move, work, and speed up or slow down by following very specific directions. M-code controls how the machine works, while G-code controls how the tool moves. If you learn these directions, you can be sure that your machining will be accurate, quick, and consistent.

These commands dictate how the tool moves, how fast it cuts, and what additional functions like stopping or cooling are activated. Here are the key codes you need to know:

- G-code tells the cutting tool how to move:

- G00: Quickly moves the tool without cutting.

- G01: Cuts at a steady speed in a straight line.

- G02 & G03: Create smooth arcs and curves that let you shape things precisely.

- M-code manages the machine’s operational functions:

- M03: Starts the spindle, making the tool spin for cutting.

- M08: Turns on the cooling to keep the engine from getting too hot.

- M30: This ends the program and sets the machine up for the next job.

Now that you know the important CNC codes, this guide on CNC G-codes covers them in detail, it’s time to put them to use. So, let’s break it down step by step so you can feel safe starting to program.

How to Write Your Own CNC Code

Sometimes, understanding how to write CNC code can feel overwhelming, but once you grasp the basics, it becomes second nature. Every CNC program begins with a setup step, where you define units, choose tools, and set up the machine. Once these initial steps are complete, you can start programming the actual cutting operations. Let’s go step by step.

Step 1: Preparation and Machine Setup

Before writing CNC code, ensure the machine and workpiece are properly set up. This includes defining material size, selecting the right cutting tool, and setting machine coordinates. These steps help prevent costly mistakes.

Preparation Checklist:

- Secure the workpiece firmly on the machine bed using a vise or clamps.

- Load the correct tool into the spindle and ensure proper tool length offsets.

- Set the work coordinate system (G54, G55, G56, etc.) based on the workpiece’s origin.

- Define tool offsets using G43 (tool length compensation) and set cutting depths appropriately.

- Activate coolant (M08) if necessary to prevent tool overheating.

Step 2: Writing the CNC Code

A CNC program is a sequence of commands that control the machine’s movement, spindle speed, and cutting operations. Here’s how to structure a simple CNC program:

- Initialize the Program: Set measurement units, safety commands, and tool positions.

- Define Spindle and Feed Rate: Assign spindle speed (RPM) and cutting feed rate (mm/min or inches/min).

- Program the Tool Path: Use G-code commands to move the cutting tool accurately.

- End the Program: Ensure the spindle stops and the machine returns to a safe position.

- End the Program – Ensure the spindle stops and the machine returns to a safe position.

Step 3: Testing and Running the Code

Before running the program on the machine, simulate it using CNC software or a dry run mode to check for errors. This helps detect any potential crashes or incorrect tool movements.

Testing Steps:

- Run the program in simulation mode to verify tool paths.

- Perform a dry run without a workpiece to check machine movement.

- Adjust spindle speeds and feed rates based on material type.

- Confirm tool offsets and cutting depths before actual machining.

By following these structured steps, you can write effective CNC programs with confidence. Always start with simple movements before advancing to complex geometries, and double-check every command to prevent errors.

Different Types of CNC Programming Techniques

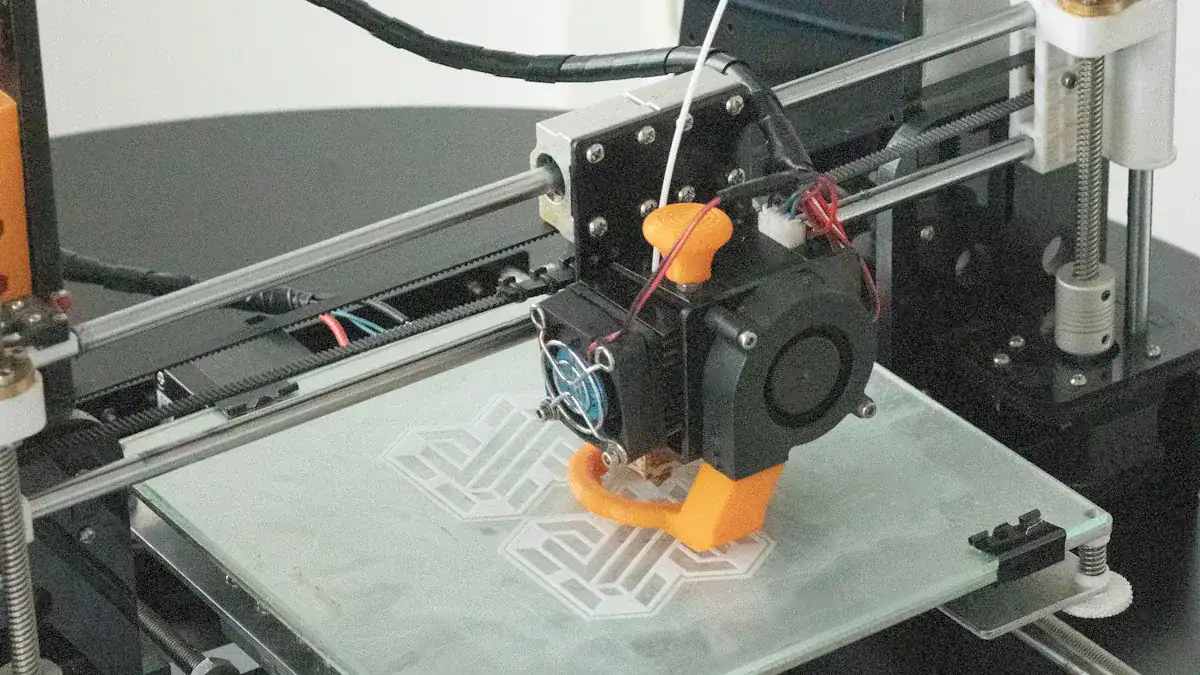

Not all CNC programming approaches are the same. Depending on the job’s complexity and the operator’s skill level, different techniques can produce accurate and efficient machining instructions. Advancements in the field, such as those highlighted in recent developments, continue to shape how these methods are applied.

But for now, computer-aided manufacturing (CAM), conversational programming, and manual programming are the three main methods to computer numerical control programming. Each one is good for different projects in its own way. So let’s look at each one separately.

Manual Programming

By writing G-code and M-code line by line, machinists operate CNC machines manually. This method is more difficult to master but allows for more precise operations and a better understanding of CNC machines.

But precision comes at a cost—every command must be entered manually, leaving no room for mistakes. A single incorrect movement or feed rate can ruin a part. Still, mastering manual programming helps machinists customize tool paths, troubleshoot errors, and make real-time adjustments without relying on software automation.

Computer-Aided Manufacturing (CAM)

Writing CNC code by hand takes time, but CAM software speeds up the process by automatically generating G-code from a digital model. This reduces errors, saves time, and simplifies complex machining tasks, making production more efficient.

And because CAM software converts designs into CNC instructions, machinists don’t need to memorize every command. Instead, they can concentrate on optimizing cutting speeds and fine-tuning toolpaths. Even with the power of CAM software, manual programming is still useful for specialized work and fast revisions.

Conversational Programming

Not everyone wants to write CNC code from scratch or deal with complex software. Conversational programming simplifies the process by letting machinists enter basic parameters like lengths and speeds, allowing the machine to generate the G-code automatically.

And since the machine handles most of the coding, operators don’t need to memorize commands or stress over minor errors. It’s perfect for quick jobs and small-batch production, but for complex designs, machinists often combine it with manual programming and CAM software for greater flexibility.

What Types of Programs Are Available for CNC?

Bringing a design to life with CNC programming isn’t just about punching in codes, it starts with the right software and the right support. With services like additional machining solutions, every exact cut, flawless edge, and flawless hole is the result of a combination of three crucial programs: CAD, CAE, and CAM. Therefore, let’s get to know each one individually.

- CAD (Computer-Aided Design): A CAD software turns rough thoughts into exact, detailed plans. Once they are finished, CAD files seamlessly integrate with CAE and CAM software, getting them ready for testing and cutting. This is why CAD is the most important part of any CNC job.

- CAE (Computer-Aided Engineering): A CAE software runs simulations to test stress, heat, and durability, helping engineers catch weak points early. Once optimized, the CAD file moves into CAM software, where it’s converted into precise CNC instructions.

- CAM (Computer-Aided Manufacturing): A CAM software takes finished designs and turns them into exact CNC instructions that tell machines how to cut, shape, and put parts together correctly. Even the best plans would not come true without it.

How to Choose the Right CNC Programming Type for Your Project

So now that you know CNC programming types, the next step is to pick the right one for your project. It’s important to choose the right method because it can save time, make things more accurate, and simplify manufacturing.

Below is a breakdown of the pros and cons of each approach to help you decide.

| CNC Programming Type | Pros | Cons |

| Manual Programming | Full control over machine operations

Ideal for simple parts and modifications No need for additional software |

Time-consuming for complex designs

Higher risk of human error Requires deep knowledge of G-code |

| CAM (Computer-Aided Manufacturing) | Automatically generates precise code

Reduces programming errors Great for complex designs and high production volume |

Less flexibility for real-time adjustments

Requires CAD models Software costs can be high |

| Conversational Programming | Quick and easy setup

No need to write full code Ideal for small-scale production and fast modifications |

Limited customization

Not suitable for highly complex parts May lack the precision of manual or CAM programming |

Therefore, every programming method has its own pros and cons, and the best one for your project will depend on your project’s demands. This detailed guide on cost-saving strategies can also help you make budget-friendly choices for your CNC program by highlighting the key factors that influence CNC machining costs.

Get a Free CNC Machining Quote from Future Parts

Understanding CNC programming is just one part of the process—turning those programs into high-quality parts requires expert machining. That’s where Future Parts comes in, providing top-tier CNC machining services that ensure accuracy, efficiency, and reliable results every time.

And choosing the right partner matters. Whether you need prototypes or large-scale production, Future Parts advanced technology and expert team guarantee consistent, high-performance results tailored to your needs. Here’s why Future Parts stands out:

- Great Tolerance Accuracy: Future Parts CNC machining services achieve ±0.01 mm precision, guaranteeing that every part meets exact specifications.

- Quick Production: Need parts fast? Future Parts provides turnaround periods of 1-3 days to prevent project delays.

- Tough Quality Control: At Future Parts each part is checked several times to make sure there are no mistakes, so you get perfect, ready-to-use parts that don’t come with any surprises.

- Expert Advice: Future Parts team helps you choose the best finishes and materials to make your plan work and doesn’t cost too much.

All you have to do if you wish to try it is forward them your CAD files and ask for a free quote. Their staff will show you what materials perform best and how to properly finish your job without making you wait a lifetime.

And if you’re eager to improve your CNC skills, there’s even more to explore. Up next, we will show you some cool tips and tricks that will help you master CNC programming.

How to Master CNC Programming for Beginners

The time and effort put into learning CNC programming will be well worth it in the end. After practicing these simple commands more often, you will become better at controlling the machine. Here are some important tips that will help you get better:

- Start with the basics: First, learn how to use G-code and M-code. These are the directions for the machine. As you get better at running the machine, it will be easy.

- Test your skills by running test programs: Do not just remember commands, try them out and see how they work. Change little things in test programs and watch how those changes affect the end result.

- Don’t be afraid to use real machines every once in a while: If you have access to CNC tools, try out real setups. There is no better way to learn how to move, how fast to move, and how accurate to be.

- Learn from machinists with experience: You could watch lessons, join online groups, or watch professionals do their jobs to learn from them. It can help you avoid making common mistakes if you watch how other people fix issues and improve their programs.

- Have patience and keep getting better: Gaining skill at CNC programming takes time, so be patient and keep practicing. Make sure you do it right the first time, and slowly improve your skills. You’ll soon be able to handle hard tasks with ease.

You’ll get better every time if you keep going. Be careful and take your time. Soon you’ll be able to handle bigger jobs. Now, let’s talk about some questions that people who are new to numerical control programming often have.

Summary

CNC programming and machining work together to turn designs into real, high-quality parts. Programming decides how accurate something is, and cutting makes it happen. It’s important to understand both when you’re making solid parts, whether you’re learning or improving your skills.

But knowledge alone isn’t enough—having the right machining partner matters too. That’s why so many choose Future Parts, where precision and quality come first. And like any skill, the more hands-on experience you get, the better you’ll be at optimizing CNC programs for flawless results.

FAQs

What is the difference between NC and CNC?

At first glance, computer numerical control (CNC) machines raise the bar for automation in a way that numerical control (NC) machines don’t. While NC machines follow directions that have already been set, CNC machines use digital programming to be more precise and flexible.

And everything changes because of that. CNC machines can easily handle complicated patterns, store many programs, and change how they move in real time. Plus, they don’t need to be reset by hand for each job like NC machines do, which speeds up and improves the efficiency of production.

What software is commonly used in CNC programming?

CNC programming relies heavily on the appropriate software to function effectively. Each piece of software is very important. CAM programs, like Mastercam and Fusion 360, write the code that computer numerical control programming uses. And CAD tools, like AutoCAD and SolidWorks, create designs with lots of details.

What is the role of a CNC programmer?

A CNC programmer is the genius behind every exact cut. They ensure that everything runs seamlessly from start to finish by creating the computer numerical control programming codes that instruct the machine on how to move, adjust speeds, and make complicated parts.

But they don’t just write code, they also make sure that the CNC program works better and fixes mistakes. They also work closely with machinists to make sure that the final product is perfect.

What safety precautions should be taken during CNC programming and operation?

Since CNC machines operate at high speeds with sharp tools, safety should always come first. Operators must wear protective gear, ensure proper machine setup, and follow lockout/tagout procedures. Double-checking code before running a program prevents collisions and keeps both the machine and user safe.