Introduction

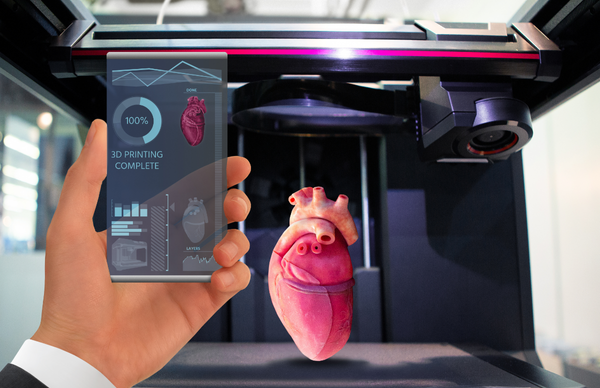

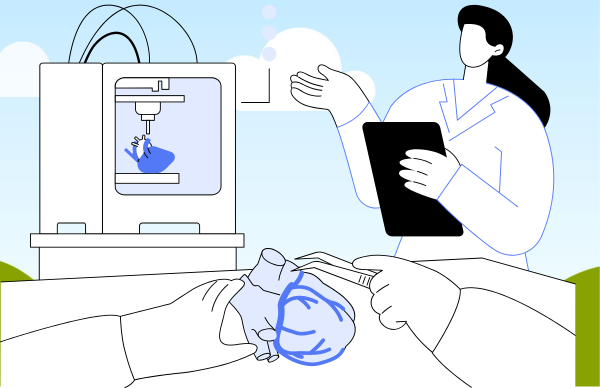

3D printing in medicine, also known as additive manufacturing, is rapidly expanding in research and clinical settings. It enables the creation of actual models of anatomical structures, which can aid in medical planning and education.

The structures to be printed are first digitally modeled. Patient-specific models are generated using advanced 3D imaging techniques such as MRI and X-ray computed tomography.

These models help hospitals and other point-of-care (POC) organizations in planning treatments more effectively. They also play a crucial role in explaining complex medical concepts to surgical patients, improving communication and understanding.

3D printing may function as a preliminary method to evaluate the outcomes of in silico experiments. These methods increase trust in new developments before expensive in vivo studies or physical testing.

Overview of 3D Printing in Medicine

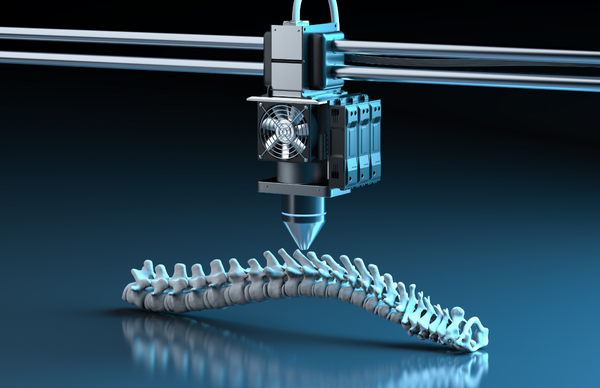

3D printing is transforming healthcare by enabling personalized medical solutions. This technology allows doctors to create patient-specific models and devices, improving treatment accuracy. For example, radiologists can print spine models to plan surgeries, while dentists can design crowns that fit perfectly.

Beyond planning, 3D printing is widely used for medical devices, including:

- Prosthetic limbs –Custom-fitted for comfort and mobility.

- Cranial implants –Designed for reconstructive surgeries.

- Orthopedic implants – Used for hip and knee replacements.

This technology reduces production costs and waiting times, allowing hospitals to create customized solutions on demand. Researchers are also exploring bioprinting, which could lead to lab-grown tissues and organs for future medical use. This innovation may revolutionize transplants and regenerative medicine.

Overall, 3D printing enhances surgery, improves prosthetics, and supports medical research. Its ability to create patient-specific solutions makes it a valuable tool in modern healthcare.

How Does 3D Printing Work in Medicine?

3D printing in medicine allows doctors to create detailed models of organs, bones, and tissues. This improves diagnosis, surgical planning, and personalized treatments such as implants and prosthetics. Using advanced imaging techniques like MRI, X-ray CT, and 3D ultrasound, doctors can capture precise anatomical structures.

A key process in 3D modelling is segmentation, where specific parts of medical images are identified and isolated. This helps convert 2D scans into 3D computer models, which can then be printed. These models assist surgeons in planning complex procedures, leading to improved precision and patient outcomes.

Beyond surgery, 3D printing also supports prosthetics and implants tailored to individual patients. Instead of relying on standard sizes, doctors can produce perfectly fitting replacements, reducing complications and enhancing comfort.

With ongoing advancements, 3D printing continues to revolutionize healthcare, offering faster, more efficient, and highly customized medical solutions.

3D Printing Application in Medicine

3D printing in medicine has grown more affordable and practical for many businesses. People in the medical field are starting to use 3D printing to make their jobs better. Here are a few of the most important ways that 3D Printing Application is used in healthcare.

Innovative Applications of 3D Printing in Medicine

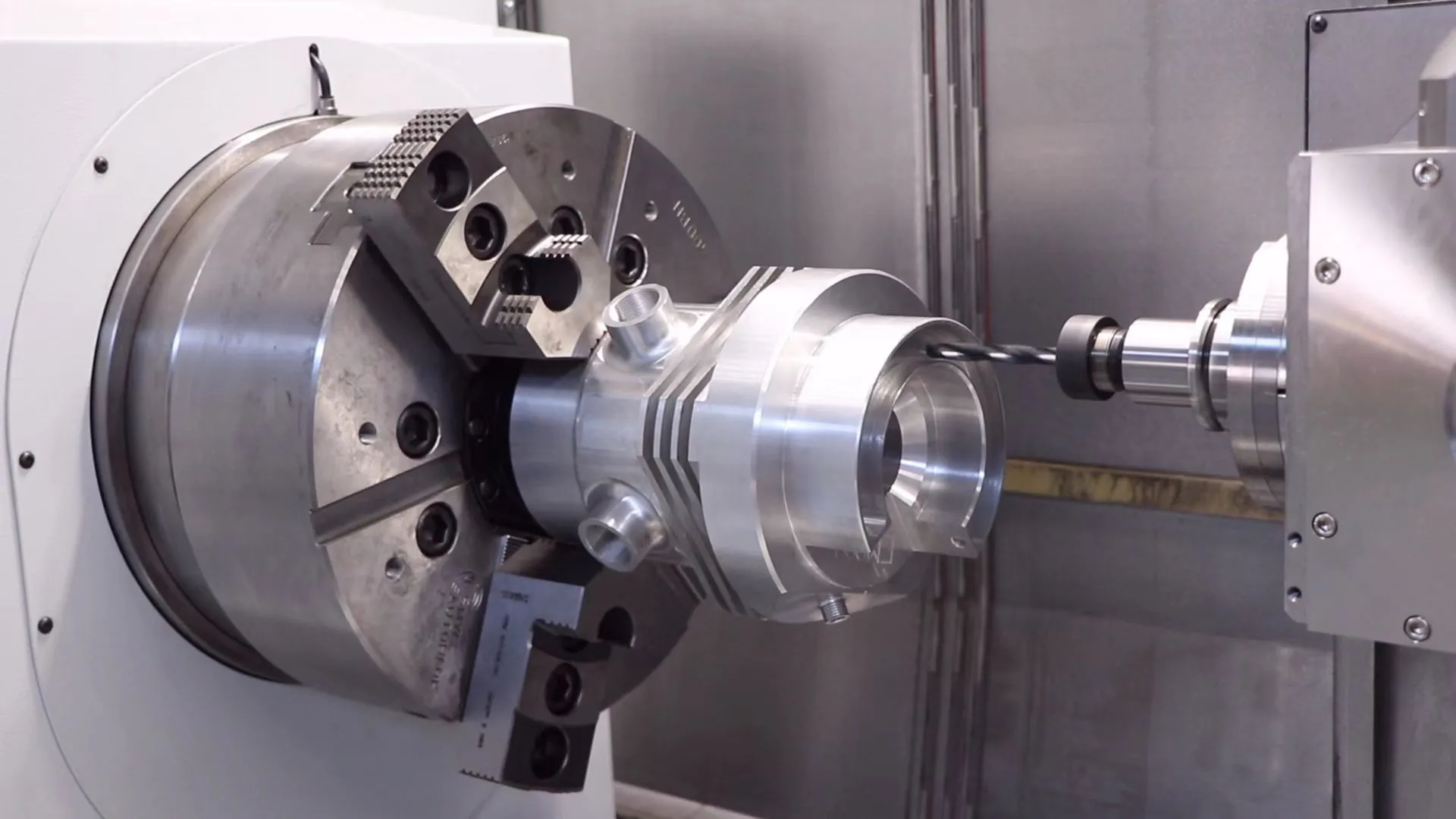

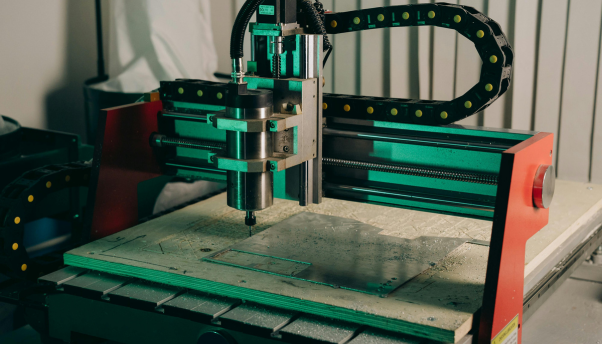

3D printing is widely used in medicine to create tools, prosthetics, and surgical models. Even when no physical objects are printed, medical professionals use CNC Machining Services to visualize complex cases and plan treatments. For example, radiologists use 3D models of organs to improve surgical precision.

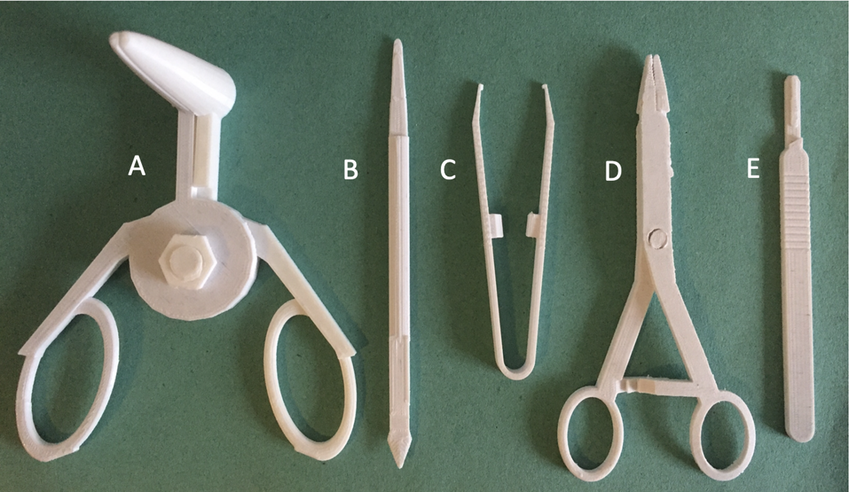

1. Customized Medical Tools

Traditional medical tool manufacturing is expensive and time-consuming. With 3D printing, healthcare workers can create customized tools in hours rather than weeks. For instance, CT scan data allows doctors to print patient-specific surgical tools, improving accuracy and reducing operation time, especially in maxillofacial surgery.

Healthcare workers use CT pictures of patients to make surgery tools that are perfectly suited for each patient. 3D printing rapidly produces customized surgical tools, improving precision and efficiency in medical procedures:

- Patient-specific surgical tools

- Custom bone saw guides

- Tailor-made forceps and clamps

- 3D-printed drill guides for dental and spinal surgeries

- Lightweight, sterilizable instruments

Having 3D printers in the medical field has been shown to shorten surgery times and improve accuracy, especially in the mouth and maxillofacial fields.

2. Personalized Prosthetics

Traditional prosthetics are costly and may not fit perfectly. 3D printing in the medical field allows the rapid production of custom-made prostheses, ensuring better comfort and function. For example, children with limb differences can receive adjustable prosthetic arms that grow with them, significantly lowering costs.

- Custom prosthetic limbs for a perfect fit

- Lightweight and durable designs

- Adjustable prosthetics for growing children

- Enhanced mobility with patient-specific designs.

alt: Prosthetic with 3D-printed components

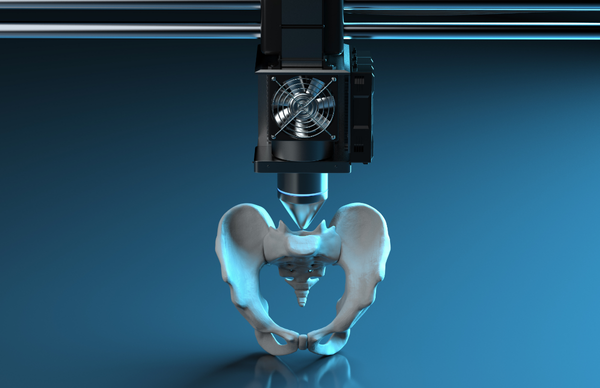

3. Bone and Joint Reconstruction

Medical 3D printing can help rebuild bones and joints in the same way that it can make replacements.

3D printing is used to rebuild bones and joints, enhancing patient recovery. Instead of standard implants, doctors can now 3D print patient-specific replacements. Applications include:

- Jawbone reconstruction for trauma patients

- Hip and knee replacements with precise anatomical fit

- Facial and breast reconstruction for cancer patients

For 3D modeling software has a huge range of options, and people are always coming up with new, creative solutions.

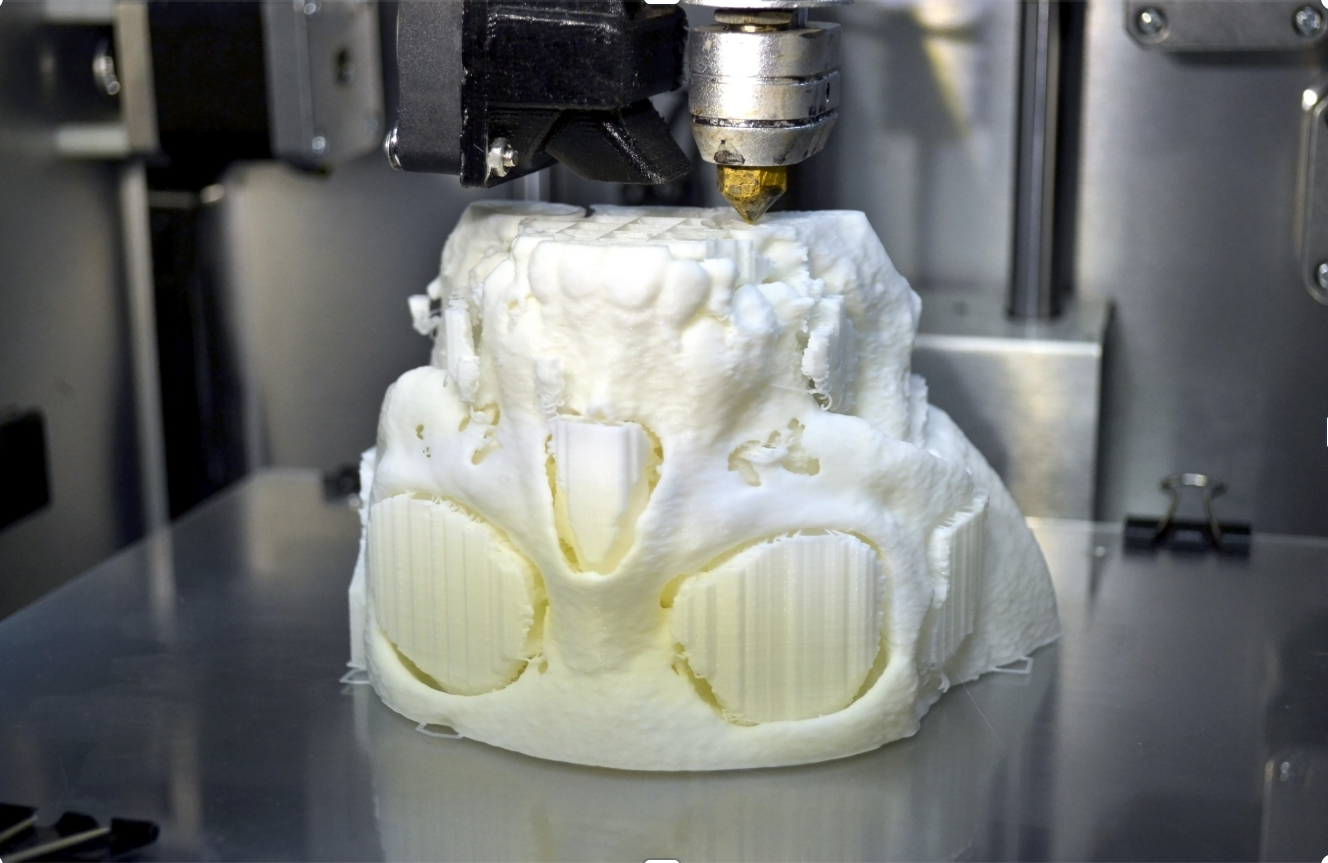

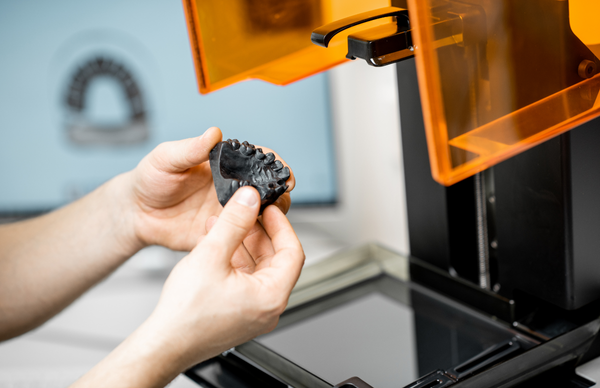

4. Dental Applications

Dentists and orthodontists use 3D printing to create custom dental solutions. Using X-ray and CT scans, they can print:

- Braces tailored to individual teeth alignment

- Crowns and bridges for a perfect fit

- Dentures that improve comfort and functionality

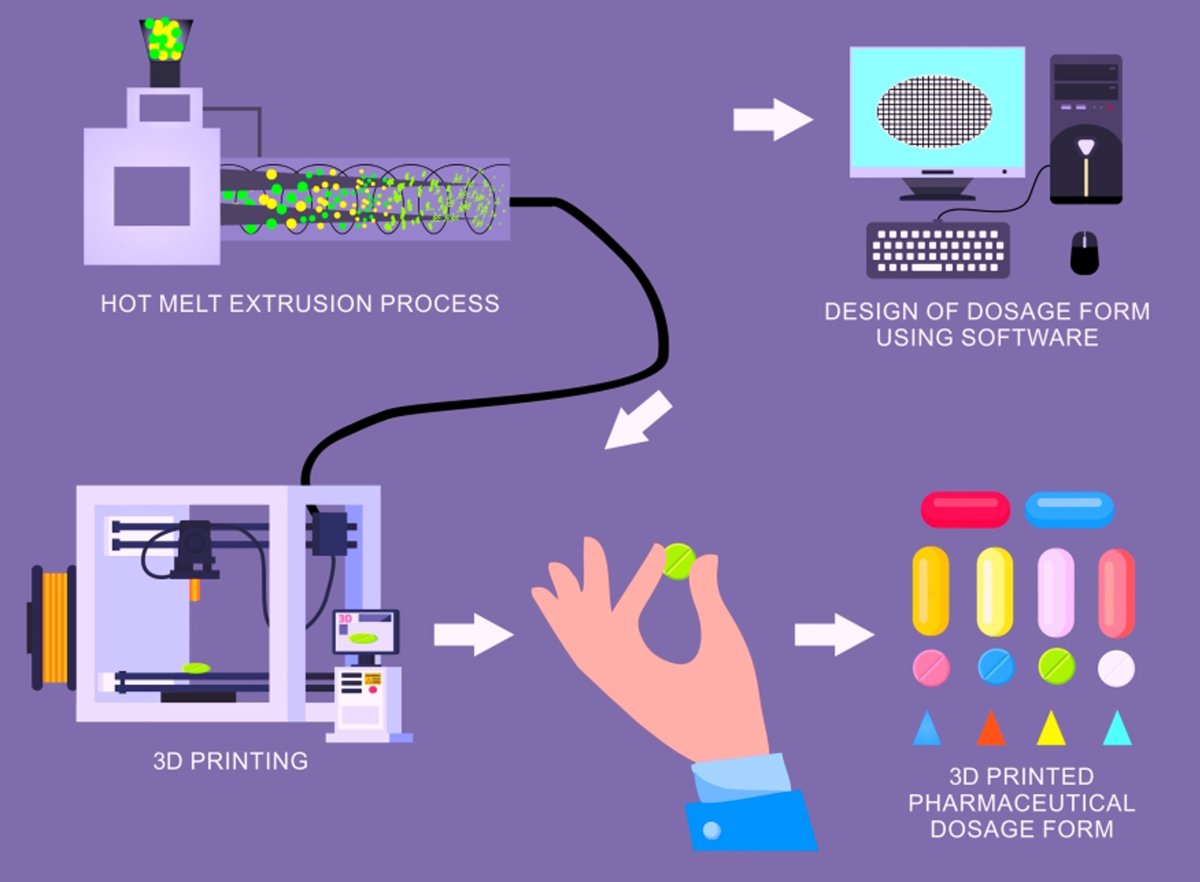

5. Pharmaceutical Applications

3D printing helps create medicines with exact doses designed for each patient. Scientists are studying how 3D-printed drugs could change the way medicines are made and supplied.

As 3D printing improves, it is making healthcare better by giving patients more effective treatments, lowering costs, and making medicines more accessible.

- Customized drug dosages for individual patients

- Rapid production of complex drug formulations

- On-demand printing of personalised medications

- Improved drug release and absorption rates

- Reduced waste in pharmaceutical manufacturing

source from: Springer Open

An example of a real-life application of 3D printing in the medical field is the SJD Barcelona Children’s Hospital planned the first difficult cancer surgery on a 5-year-old boy in 2013, which went very well. Neuroblastoma is a rare childhood cancer that starts in nerve cells. It was found in the boy. Surgeons had to be very careful not to cut any blood vessels or organs nearby to remove the growth without putting the patient’s life at risk.

3D Printing in Medicine Pros and Cons

| Advantages of 3D Printing | Disadvantages of 3D Printing |

| Flexible Design – Enables intricate and customized designs. | Limited Material Options – Restricted selection of materials. |

| Rapid Prototyping – Quick production of prototypes within hours. | Small Build Volume – Large objects require assembly. |

| Cost-Effective – Reduces manufacturing time and costs. | Design Accuracy Issues – Some printers require post-processing for precision. |

| Greater Accessibility – More services available locally and online. | Intellectual Property Concerns – Increased risk of counterfeit designs. |

| Medical Advancements – Enables prosthetics, implants, and bioprinting. | High Initial Costs – Industrial 3D printers and materials are expensive. |

Enhancing Medical Applications with On-Demand Manufacturing Services

The healthcare industry gains support from Future Parts, a trusted on-demand manufacturing service that provides innovative solutions for medical applications. Using state-of-the-art additive manufacturing systems, the company produces highly precise medical components, including surgical tools and patient-specific implants.

Why Choose Future Parts for 3D Printing in Medicine?

- Advanced 3D Printing Technologies: They uses Stereolithography (SLA) along with selective Laser Sintering (SLS) fused Deposition Modeling (FDM) and Direct Metal Laser Sintering (DMLS) for producing medical components.

- High Precision and Biocompatibility: Patient-relevant requirements for precision alongside biocompatibility by the medical-grade materials.

- Customization and Rapid Prototyping:Medical experts at the company create patient-specific designs to evaluate pre-implementation solutions before clinical implementation.

Key Services Offered

- The company uses prototype development to test and create new medical tools quickly.

- Engaging medical practitioners with Surgical Planning Models grants them access to detailed anatomical models.

- Safe and durable materials for direct patient applications.

How to Collaborate with Future Parts

Here are the steps to collaborate with Future Parts:

- Place an order online– Visit Future Parts’ digital platform and find the inquiry form button.

- Request a Quotation –Submit an fast quotation inquiry through their form, specifying the parts or services you require.

- Receive a Quick Response –Their team will review your request and provide a prompt response.

- Explore Partnership Opportunities –Reach out via email or phone to discuss long-term collaboration or customised solutions.

- Engage Directly with Their Team –Communicate with Future Parts’ experts to ensure a smooth and efficient partnership process.

3D Printing Materials and 3D Printers Used in Healthcare

Materials and printing technology are selected based on three important factors: biocompatibility, strength, and precise operation.

Common 3D Printing Materials in Healthcare

Biocompatible Polymers:

The medical industry utilizes polymers, which show low reactivity toward biological substances, to create prosthetics. Examples:

- Polylactic Acid (PLA): Biodegradable and safe for temporary medical applications.

- Polyether Ether Ketone (PEEK): The application of Polyether Ether Ketone (PEEK) material brings implant devices strong resistance to heat combined with its implant-grade properties.

- Thermoplastic Polyurethane (TPU): There exists an application for flexible medical materials based on thermoplastic polyurethane (TPU) in soft tissues.

Metals for Implants and Tools

The combination of implants and surgical tools requires metal components to maintain their strength.

- Titanium (Ti-6Al-4V); Used for bone implants, joint replacements, and dental implants.

- Stainless Steel: Common in surgical instruments and orthopedic implants.

- Cobalt-Chrome Alloys:Used in high-stress applications like hip and knee replacements.

Hydrogels and Bioinks:

Hydrogels, together with Bioinks, serve as essential components for tissue engineering applications.

- Collagen-based Bioinks:Bioink materials made from collagen exist to create tissue models for scientific research and medical grafts.

- Alginate and Gelatin Hydrogels: The tissue scaffolds receive growth support from Alginate and Gelatin Hydrogels as culturing medium.

Types of 3D Printers Used in Healthcare

source from Bitfab

- Stereolithography (SLA) Printer:Achieves high precision through resin printing, which produces dental models, surgical guides, and implants.

- Selective Laser Sintering (SLS) printer: The system processes powdered PEEK materials to produce durable medical equipment that is also heat resistant.

- Fused Deposition Modeling (FDM) Printers: Suitable for producing prosthetics, braces, and anatomical models.

- Direct Metal Laser Sintering (DMLS) and electron Beam Melting (EBM) Printers: Used for titanium and cobalt-chrome implants.

- Bioprinters:Specific equipment for scaffold structures using bio-inks combined with living cells.

What is the future of 3D printing in medicine?

Customizing prostheses and implants using 3D printing is a medical breakthrough. Traditional approaches struggle to make patient-specific devices. 3D printing allows surgeons to build patient-specific prostheses and implants.

Bioprinting may be the most innovative medical 3D printing in medicine. Patient-compatible organs and tissues may lessen donor demand, which would lessen organ rejection and save lives.

The future of healthcare 3D printing extends beyond labs and industries. As technology progresses, point-of-care 3D printing may occur. Hospitals and clinics may employ 3D printers to customize medical devices, implants, and drugs.

Physicians will utilize this technology extensively. Private companies will help providers incorporate 3D printing into their ecosystem to decrease costs and risks.

Conclusion

3D printing in medicine can revolutionize the healthcare industry, particularly in terms of its capacity to manufacture products that are highly personalized at the point of care. But this situation also makes it hard to keep an eye on things. As more people use 3D printing, the laws overseeing it need to change too. They need to make sure that the benefits of the technology exceed the risks.

FAQS:

Q: How much does 3D printing cost?

A: For the majority of individuals, operating 3D printers is often not costly. The primary expenses consist of printing materials, power, and maintenance. These expenses are often minimal for residential users and enthusiasts. Additionally, FP offers a free inquiry and free Design for Manufacturability (DFM) service, helping users optimize designs and reduce unnecessary costs, making 3D printing even more accessible and affordable.

Q: What kinds of materials are used in medical 3D printing?

A: Most medical 3D printing biomaterials, including metals, ceramics, hard polymers, and composites, are stiff and utilized for orthodontics.

Q: What are 3D-printed organs?

A: A 3D bioprinter creates a tissue copy. Bioink prints artificial organs and tissues. The bioink helps cells construct the function and structure of the mimicked organ.

Q: When was 3D printing first used in medicine?

A: The healthcare sector began the use of 3D printing in 2000, and in the subsequent year, the inaugural synthetic scaffolds for human bladder tissue were produced employing this technology.

Disclaimer

This information provides educational and informative content only. 3D printing in healthcare is a quickly growing area; therefore, the specifics may not reflect the advances or regulatory changes.

Medical practitioners and organizations should contact specialists and follow health standards before using 3D printing. Future Parts and other firms are provided for information only, not medical advice.

Before utilizing 3D-printed medical materials, equipment, or implants, consult a specialist.