About Future Parts

Our Story

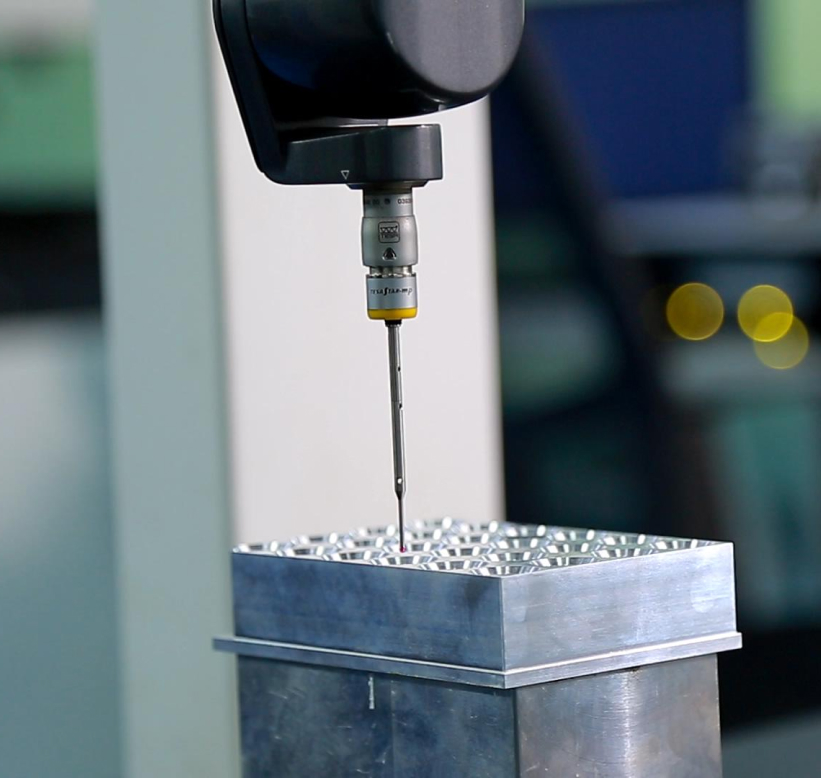

Future Parts was formed in 2018 by a collective of like-minded partners with the intention of offering high-quality CNC machining services.

Our business quickly grew, prompting significant investments into cutting-edge equipment as we achieved ISO, QMS, EMS and IATF 16949 certification to guarantee precision products.

Over time, our services have grown to encompass in-house design, production and testing for clients across 50+ countries worldwide.

By 2024, we had become industry leaders. Today, we continue our expansion by adopting cutting-edge technologies and leading manufacturing into its future.

Our Milestones

2018

Founding

2019

Market Expansion

2020

Certification & Quality Control

2021

Service Diversification

2022

Innovation & R&D

2023-2024

Continued Growth

Why Choose Future Parts

Reliable Partner

Future Parts has a production capacity of 500,000 pieces per year and has successfully served over 800 customers worldwide, delivering high-quality solutions.

Excellent Quality

Our factory is ISO, QMS, and EMS certified to meet international standards. With a 95% customer satisfaction rate, we are trusted globally by leading companies.

Cost-effective Solution

Future Parts' DNA

We deliver innovative precision through advanced technology and meticulous craftsmanship, helping businesses turn their ideas into reality.

To be the global leader in precision, setting the benchmark for quality and innovation in prototyping and on-demand manufacturing.

We set the bar high in every part we produce, ensuring excellence in every piece, from design to delivery.

From Our CEO

Future Parts’ aim is simple yet ambitious: we seek to foster innovation while offering reliable manufacturing services that satisfy current and future customer requirements.

Future Parts has achieved its aim through meticulous craftsmanship and an unwavering adherence to quality commitment in each product that leaves its facility.

As we expand in manufacturing, we remain true to our core values of quality, integrity, and customer service.

We take great pleasure in offering customized solutions tailored specifically for each of our client goals–be they precision machining services or assembly services offered from us.

Experienced team, advanced technologies and customer-first focus combine with our commitment to continual improvement and sustainability to enable us to meet and surpass even the highest standards.

When new demands emerge we not only meet them immediately but can quickly anticipate new ones too!

Thank you for choosing Future Parts as your manufacturing partner! Together we are helping to shape the future of manufacturing.

CEO, Future Parts

Future Parts' Core Members

With 20+ years in manufacturing, I’ve held roles like production worker, planner, sample assistant, textile CSR, sales assistant, and director’s aide.

This experience helps me maintain strong client relationships and continuously improve my skills to support the company’s growth and success.

With 22 years in the mechanical industry, I spent over 10 years on the shop floor, gaining extensive hands-on experience and mastering various machining processes.

Later, I focused on process analysis, blueprint review, and cost evaluation, ensuring technical precision and cost efficiency. I am a seasoned, versatile professional in the mechanical field.

With 12+ years in manufacturing, I started with 5 years in machining and surface treatment, building a solid foundation in production tech. For the past 7 years, I’ve focused on procurement and cost optimization.

My machining background helps me understand production needs, ensuring we always get the best materials and services, while continuously improving procurement strategies to support company growth.

I started my career with 6 years as a machining worker, gaining deep production knowledge.

For the past 4 years, I’ve focused on project management and team communication, using my machining experience to understand technical details, anticipate challenges, and ensure smooth project progress by addressing issues early and minimizing delays.

With 10+ years in quality control, I ensure products meet the highest standards of quality and precision.

I have extensive experience in supervising inspections, implementing quality protocols, and identifying issues before production. My focus on excellence drives continuous improvement, ensuring all products meet regulatory and customer expectations.

With 14 years of experience, including 9 in machining, I’ve worked as an HR clerk and order follow-up clerk.

Currently, as an order clerk, I coordinate with multiple departments to ensure timely deliveries and customer satisfaction. We are committed to providing the best quality to our clients.

Future Parts' Core Members

With 20+ years in manufacturing, I’ve held roles like production worker, planner, sample assistant, textile CSR, sales assistant, and director’s aide.

This experience helps me maintain strong client relationships and continuously improve my skills to support the company’s growth and success.

With 22 years in the mechanical industry, I spent over 10 years on the shop floor, gaining extensive hands-on experience and mastering various machining processes.

Later, I focused on process analysis, blueprint review, and cost evaluation, ensuring technical precision and cost efficiency. I am a seasoned, versatile professional in the mechanical field.

With 12+ years in manufacturing, I started with 5 years in machining and surface treatment, building a solid foundation in production tech. For the past 7 years, I’ve focused on procurement and cost optimization.

My machining background helps me understand production needs, ensuring we always get the best materials and services, while continuously improving procurement strategies to support company growth.

I started my career with 6 years as a machining worker, gaining deep production knowledge.

For the past 4 years, I’ve focused on project management and team communication, using my machining experience to understand technical details, anticipate challenges, and ensure smooth project progress by addressing issues early and minimizing delays.

With 10+ years in quality control, I ensure products meet the highest standards of quality and precision.

I have extensive experience in supervising inspections, implementing quality protocols, and identifying issues before production. My focus on excellence drives continuous improvement, ensuring all products meet regulatory and customer expectations.

With 14 years of experience, including 9 in machining, I’ve worked as an HR clerk and order follow-up clerk.

Currently, as an order clerk, I coordinate with multiple departments to ensure timely deliveries and customer satisfaction. We are committed to providing the best quality to our clients.

Work & Life at Future Parts