What is CNC Milling, Milling Basic Principles

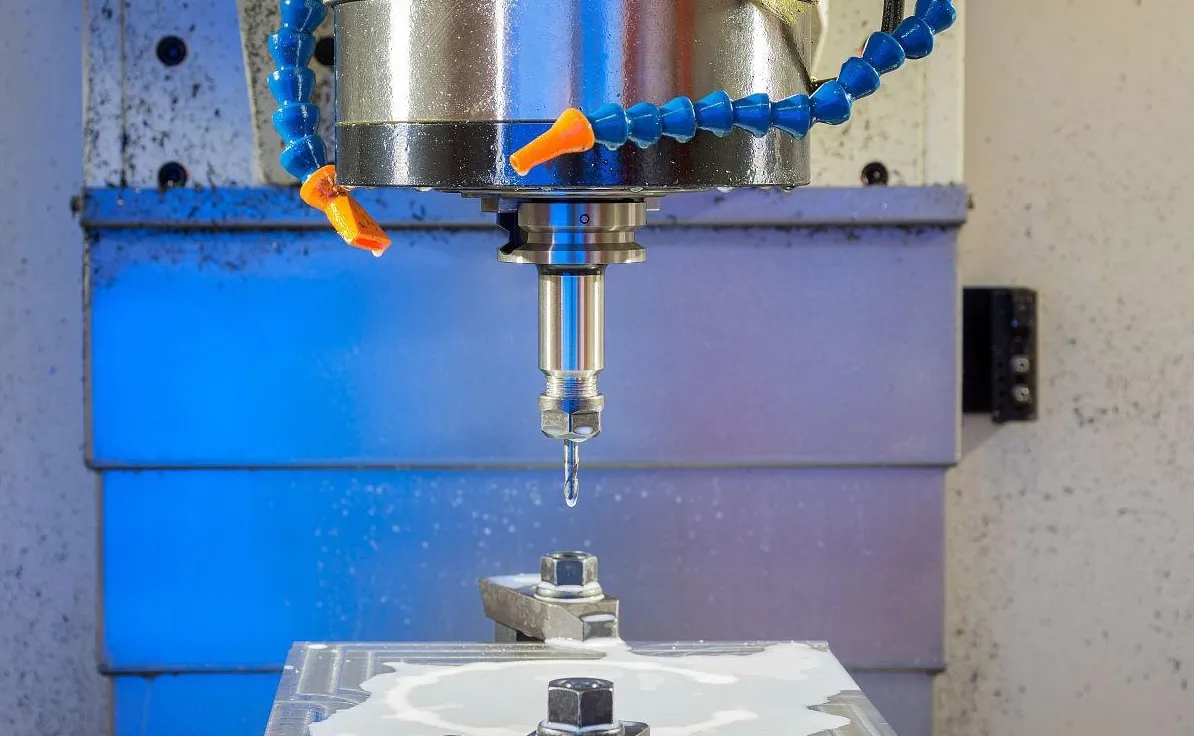

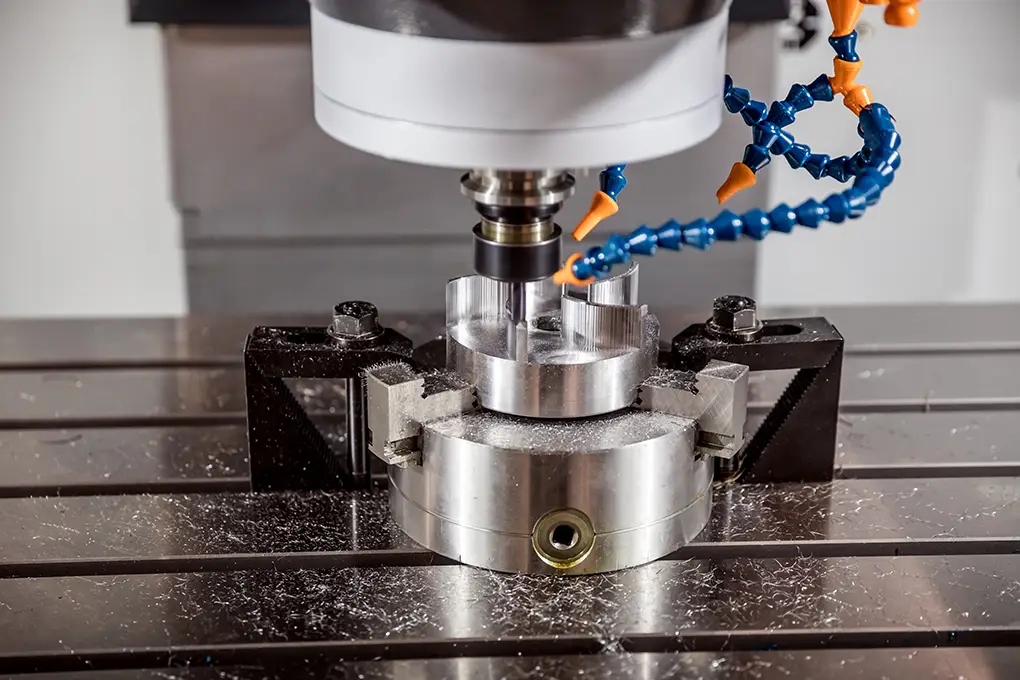

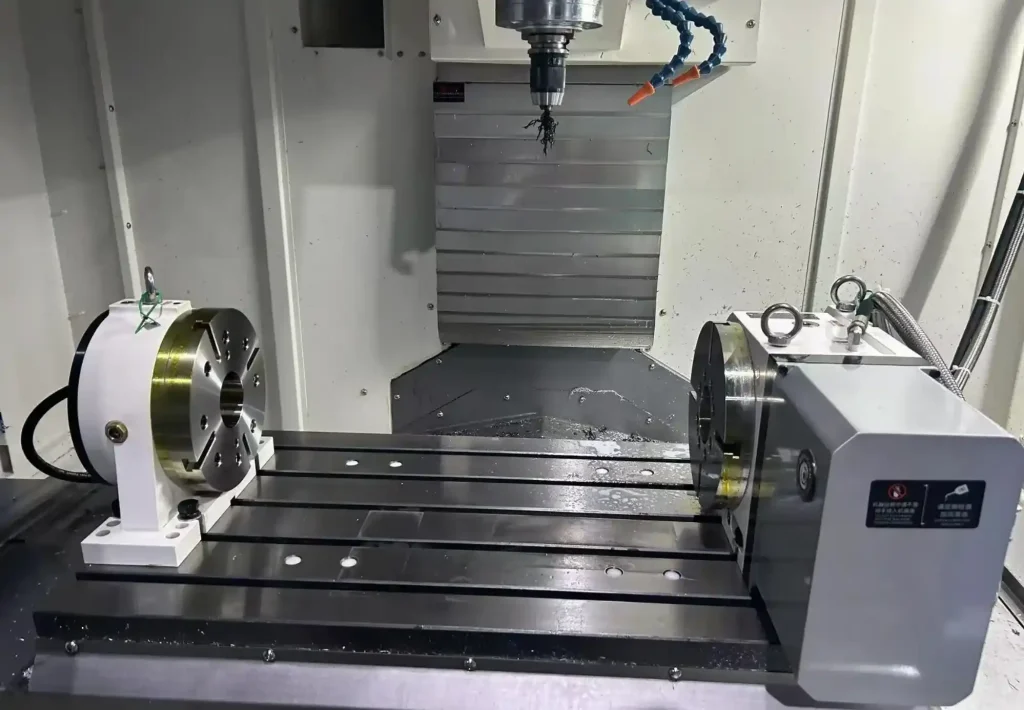

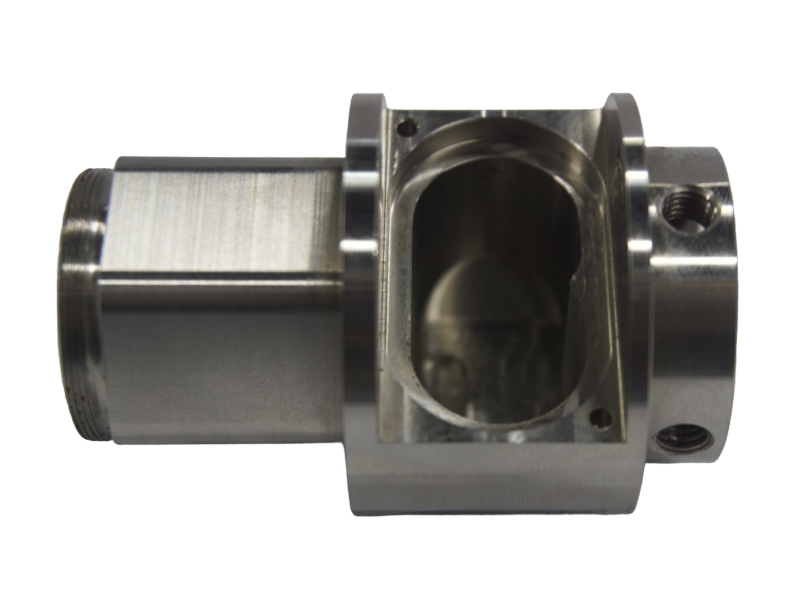

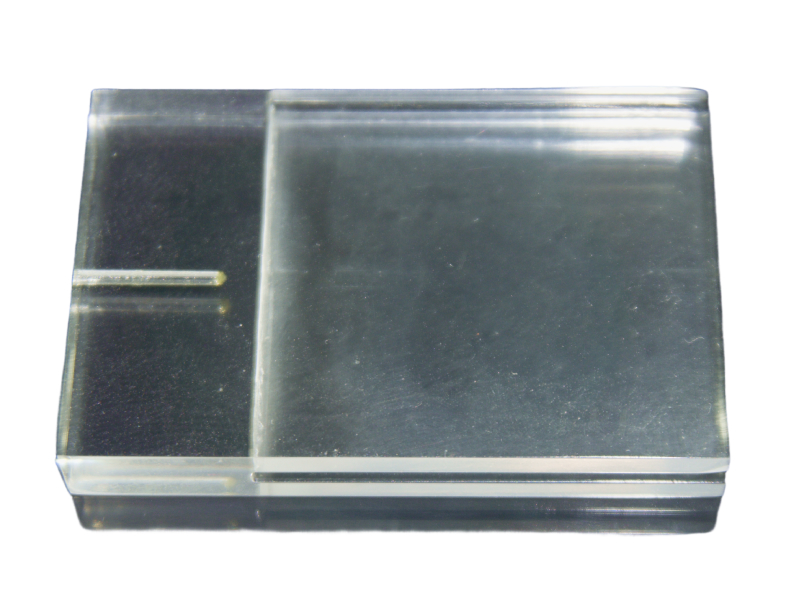

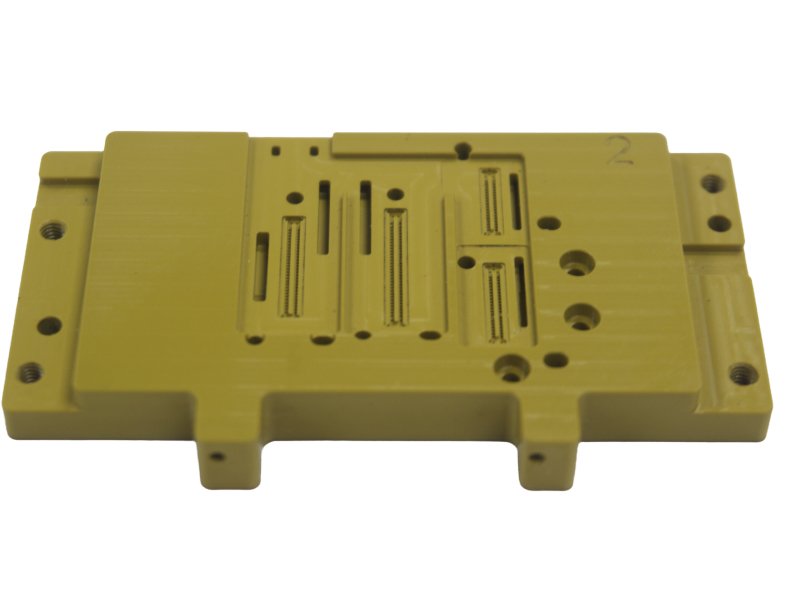

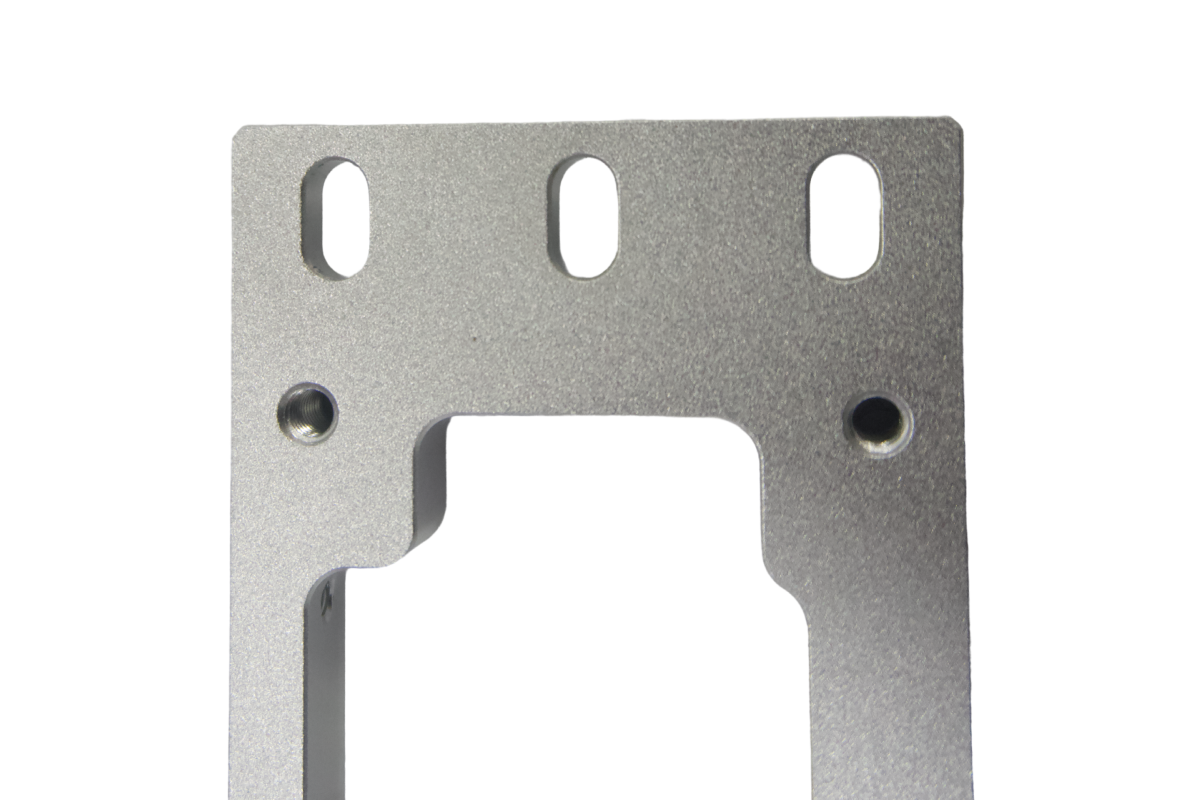

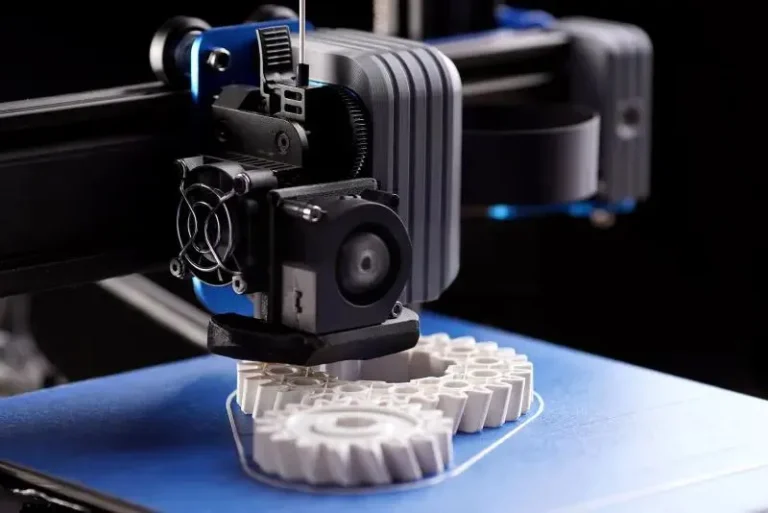

CNC milling machining is a metal cutting process widely used in manufacturing that removes material from a workpiece by using a rotating milling cutter to achieve the desired shape, size, and surface quality.

Milling is one of the most commonly used processes in machining, with the advantages of high efficiency, precision, and flexibility, and is widely used in various industries such as aerospace, automotive, mold and die, and machinery.

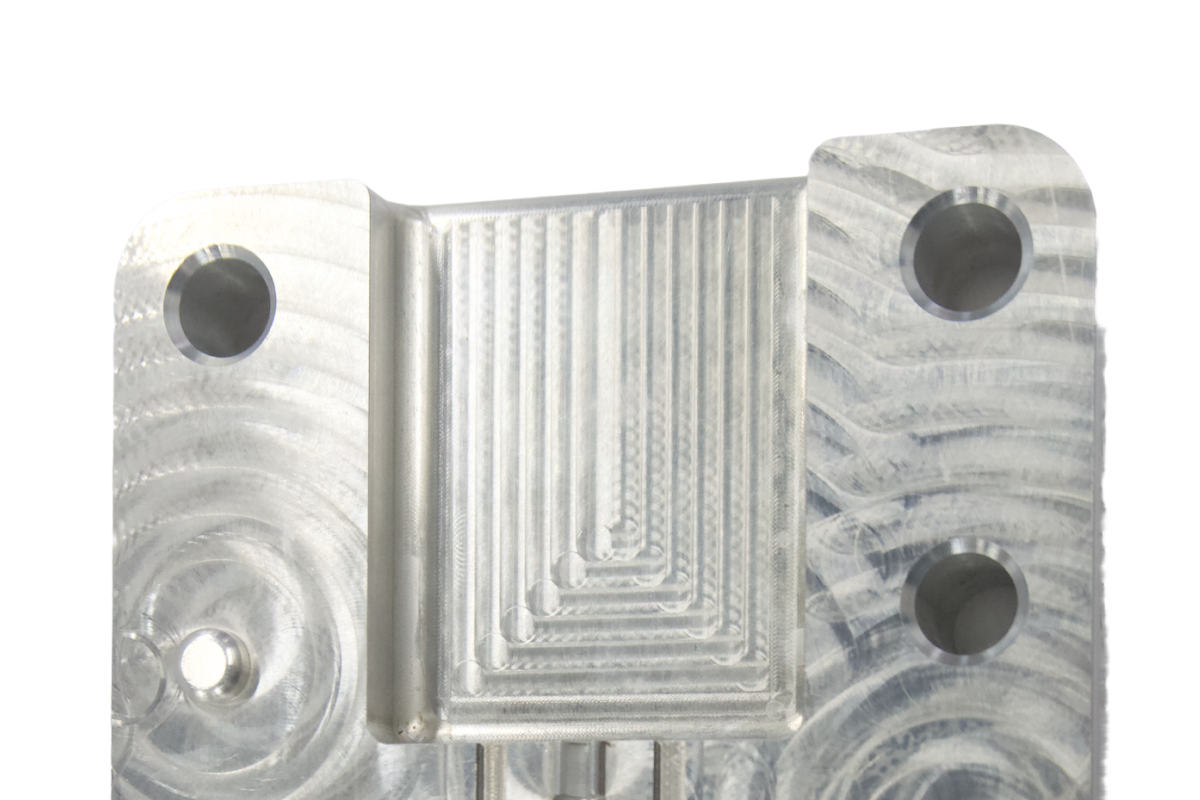

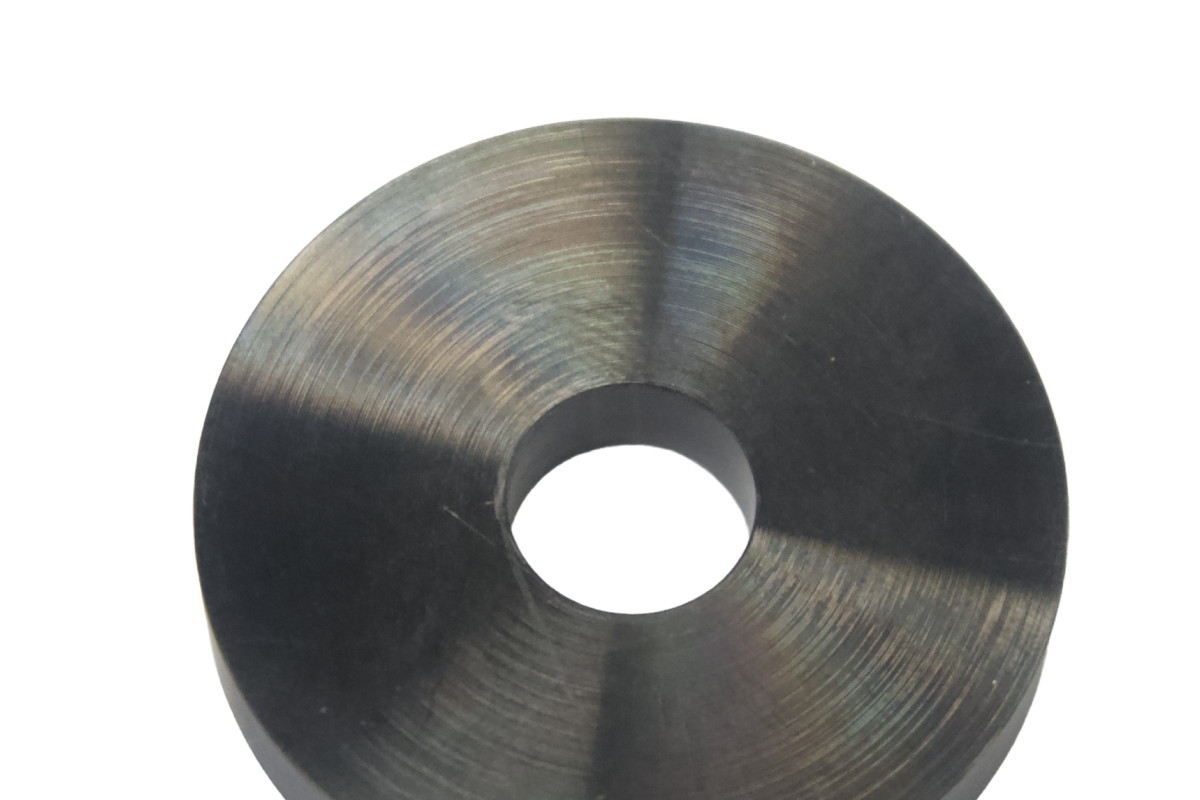

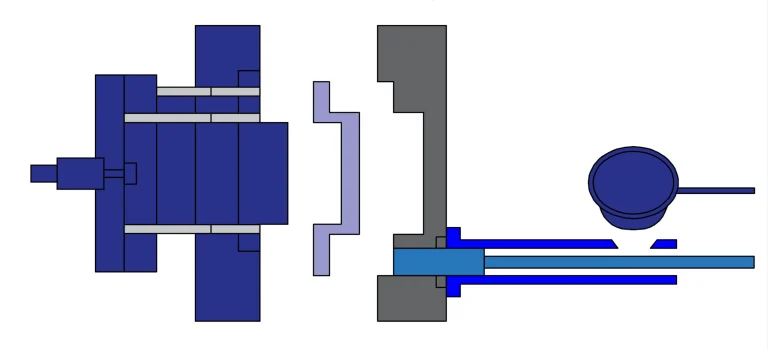

The basic principle of milling is to utilize the rotary motion of the milling cutter and the feed motion of the workpiece to create a relative motion between the milling cutter and the workpiece, thus gradually removing the material from the workpiece.

The shape and size of the milling cutter vary according to the machining requirements and can be of various shapes, such as straight flute, beveled flute, ball end, end mill, and so on. When milling, the high-speed rotation of the cutter and the feed rate of the workpiece need to be precisely controlled to ensure machining accuracy and surface quality.