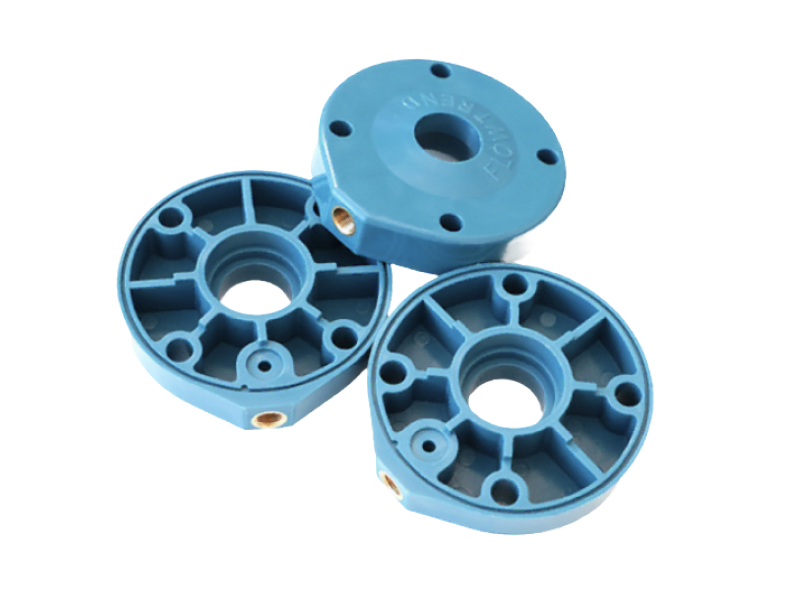

Injection Molding Services

Upload your design today for a free quote and DFM analysis, and get your custom molded prototypes and production parts ASAP. Choose from over 100 thermoplastic and thermoset materials for prototypes and plastic parts.

- Production-grade steel tooling

- No minimum order quantities

- T1 samples as fast as 2 weeks

Start a New Injection Molding Quote

- All uploads are secure and confidential.

40+

Injection Molding Machines

ISO

9001,14001Certified

Our Injection Molding Capabilities

Our Factory for Custom Injection Molding Services

Injection Molding Factory

Machine: 5 Large Injection Molding Machines

Expertise: Fast production of complex-shaped, dimensionally stable plastic products.

Location: Dongwan

Injection Molding Plant

Machine: 40 Injection Molding Machines

Expertise: Rapid production of various complex-shaped, dimensionally accurate plastic products.

Location: Dongwan

Why Choose Us

Professional Mold Tooling

Our team designs and crafts each mold from high-quality steel or aluminum for optimal performance and durability in both short and long production runs.

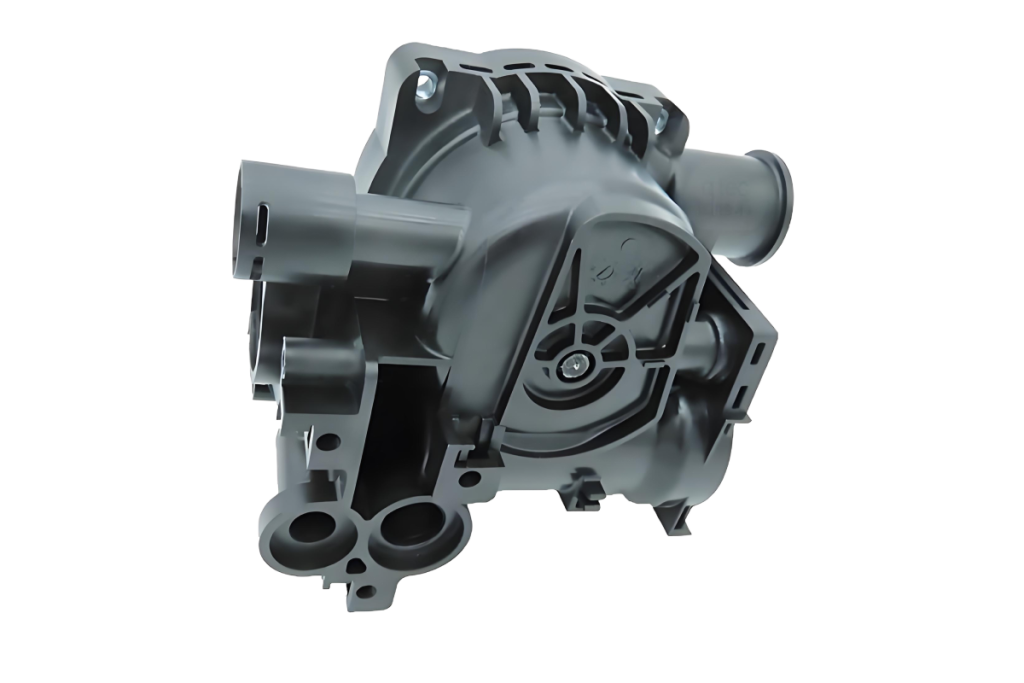

High Quality Plastics Parts

Whether for prototypes, low-volume, or high-volume production, Future Parts ensures every molded part meets top quality standards for performance and aesthetics.

Fast Lead Time

Future Parts delivers fast production with 40+injection molding machines running 24/7, ensuring quality for both prototypes and large-scale runs.

Start Your Injection Molding Project Today!

Need high-quality, precise parts for your project? Contact us now to get custom injection molded parts that meet your specifications with fast lead times and competitive pricing.

Injection Molding Materials

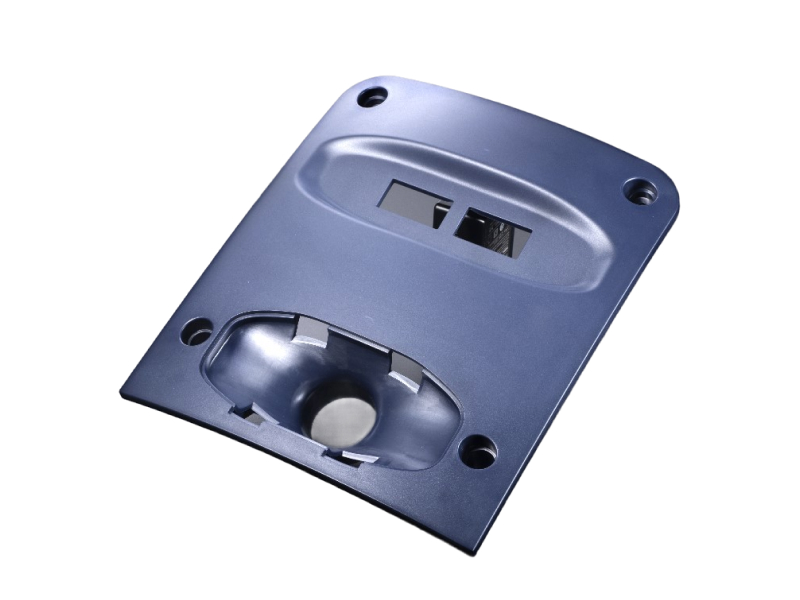

ABS

ABS is a highly popular material for injection molding due to its rigidity, versatility, and excellent chemical and weather resistance. Often combined with chrome plating, it is commonly used to produce high-quality automotive accessories and other durable components.

White

Black

| Color: | Beige, Black, White |

| Price: | $$ |

| Build Time: | 3 to 5 Business Days |

| Subtypes : | ABS Beige (Natural), ABS Black, ABS Black Antistatic, ABS Milky White, ABS+PC Black, Flame Retardant ABS Beige, Flame Retardant ABS Black. |

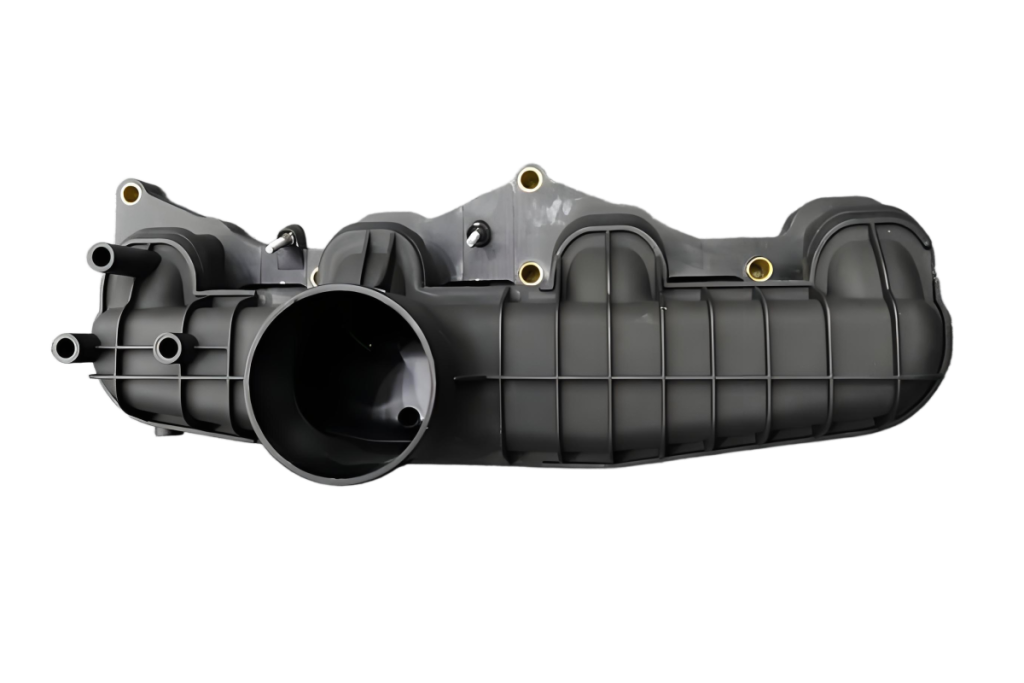

PA

PA (or nylon) plastic injection molding material is a versatile, durable, and flexible material that can be used in a wide range of applications. Due to its high melting point, it is an excellent alternative to metal components in high-temperature environments, such as car engines and other types of high-friction machinery.

White

| Color: | Blue, Black, Beige |

| Price: | $$ |

| Build Time: | 3 to 5 Business Days |

| Subtypes : | PA(Nylon) Blue, PA6 (Nylon)+GF15 Black, PA6 (Nylon)+GF30 Black, PA66 (Nylon) Beige(Natural), PA66 (Nylon) Black |

PC

PC (Polycarbonate) offers excellent impact resistance, wear resistance, and the ability to withstand functional testing. It is commonly used in industries such as medical, automotive, and telecommunications for its durability and reliability.

Transparent

| Color: | White, Black |

| Price: | $$ |

| Build Time: | 3 to 5 Business Days |

| Subtypes : | Flame Retardant Transparent PC, Food Grade PC-Transparent, PC Black, PC Transparent, PC White, PC Yellowish White, PC+GF30 Black |

PE

Polyethylene is lightweight, durable, and impact-resistant, making it ideal for packaging, containers, and piping. Its excellent chemical resistance and durability also make it perfect for outdoor and high-moisture environments.

White

Black

| Color: | White, black |

| Price: | $$ |

| Build Time: | 3 to 5 Business Days |

| Subtypes : | PE Black, PE White |

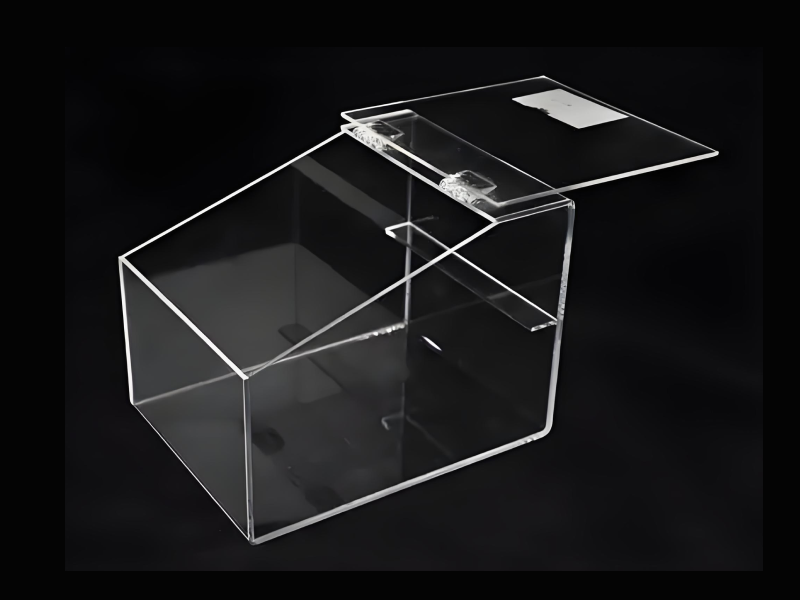

PMMA (Acrylic)

Acrylic (PMMA) injection molding is an effective method for producing high-quality, clear, and transparent parts and prototypes. Using an SPI Grade A mold finish ensures optimal clarity and smooth surface quality.

Transparent

| Color: | Black, White |

| Price: | $ |

| Build Time: | 3 to 5 Business Days |

| Subtypes : | PMMA Black, PMMA Transparent, PMMA White |

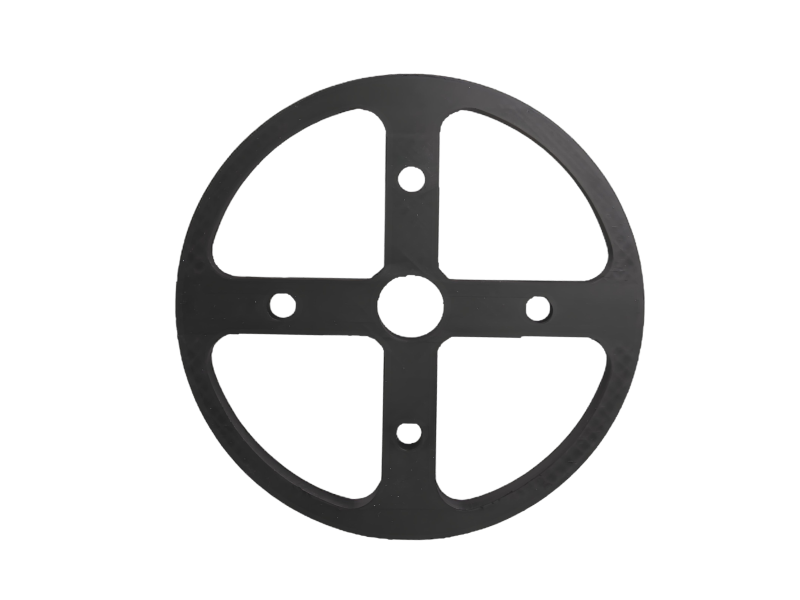

POM

POM is a high-performance plastic known for its excellent dimensional stability, low friction, and high strength. It is widely used in precision mechanical parts such as gears, bearings, and other components that require high accuracy and durability under stress.

Transparent

| Color: | Black, White, Blue, Dark brown |

| Price: | $$ |

| Build Time: | 3 to 5 Business Days |

| Subtypes : | Dark Brown (Coffee) POM 100AF, POM Black, POM Blue, POM White |

PP

Polypropylene (PP) is a durable thermoplastic polymer commonly used in injection molding. Known for its strength and resistance to various external factors, it is considered a safe and reliable material choice for a wide range of applications.

Transparent

| Color: | Black, White, Custom |

| Price: | $ |

| Build Time: | 3 to 5 Business Days |

| Subtypes : | PP Black, PP White, PP+GF30 Black |

PVC

PVC is a versatile and affordable material known for its excellent chemical resistance and durability. It’s commonly used in plumbing, medical devices, electrical cables, and construction materials thanks to its strength and flexibility.

PTFE

PTFE is renowned for its outstanding chemical resistance and low friction characteristics, making it ideal for use in non-stick coatings, gaskets, seals, and bearings. It excels in harsh environments, withstanding high temperatures and exposure to aggressive chemicals.

Transparent

| Color: | Black, White |

| Price: | $ |

| Build Time: | 5 Business Days |

| Subtypes : | Teflon (PTFE) Black, Teflon (PTFE) White |

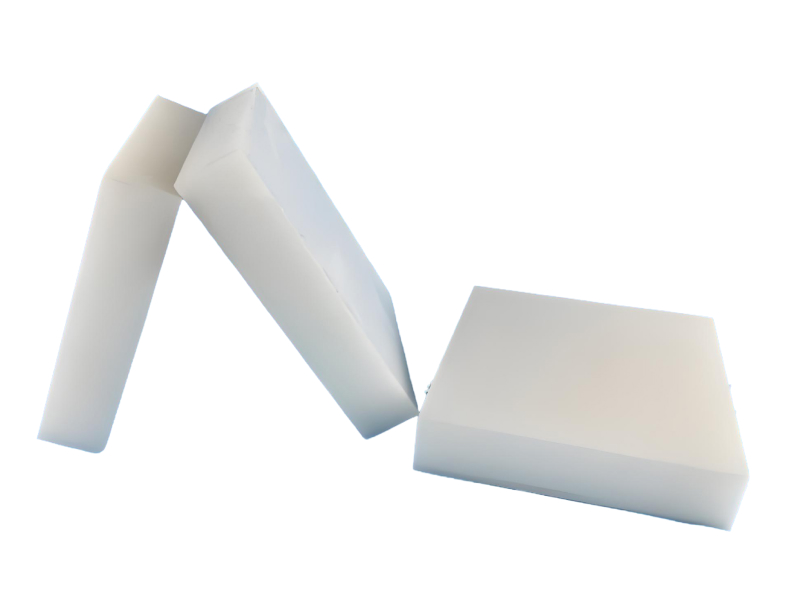

UPE

UPE is a strong, durable material known for its exceptional abrasion resistance. It is commonly used in high-wear applications like chute linings, hoppers, and conveyor systems, where impact resistance is essential.

Transparent

| Color: | Black, White |

| Price: | $$ |

| Build Time: | 5 Business Days |

| Subtypes : | UPE Black, UPE White |

LDPE

LDPE is soft, flexible, and offers excellent sealing properties, making it widely used in plastic bags, tubing, and films. Its flexibility and ease of processing make it perfect for applications that require heat sealing or stretchability.

PBT

PBT is a strong, heat-resistant material recognized for its rigidity and dimensional stability. It is commonly used in automotive, electrical, and electronics applications, such as connectors and housings.

Transparent

| Color: | Black, Milky White |

| Price: | $$ |

| Build Time: | 5 Business Days |

| Subtypes : | PBT Black, PBT Milky White(Natural) |

PET

PET is a strong, chemical- and moisture-resistant material used in various applications, including food containers, beverage bottles, and textiles. Its durability and recyclability make it a preferred choice for packaging.

Transparent

| Color: | Black, White |

| Price: | $ |

| Build Time: | 5 Business Days |

| Subtypes : | PET Black, PET White, PET+GF30 Black, PET+GF30 White |

PPS

PPS offers exceptional chemical resistance and heat stability, making it perfect for automotive, aerospace, and industrial applications. It is commonly used for components that endure high temperatures and exposure to harsh chemicals.

Transparent

| Color: | Black, White |

| Price: | $$ |

| Build Time: | 5 Business Days |

| Subtypes : | PPS Black, PPS White, PPS+GF30 Black, PPS+GF30 White |

PS

PS is lightweight and easy to machine, making it ideal for models, prototypes, and low-strength applications. Its ease of molding also makes it a popular choice for packaging and disposable products.

Transparent

| Color: | Transparent |

| Price: | $$ |

| Build Time: | 5 Business Days |

| Subtypes : | PS Transparent |

HIPS

High-impact polystyrene is easy to process and machine, providing excellent impact resistance and dimensional stability. It is commonly used in prototyping, displays, and packaging because of its ease of molding and processing.

Transparent

| Color: | White |

| Price: | $$ |

| Build Time: | 5 Business Days |

| Subtypes : | HIPS Board White |

HDPE

High-density polyethylene provides an excellent strength-to-density ratio, along with impact resistance and durability. It is commonly used for making bottles, corrosion-resistant pipes, and plastic lumber due to its ability to withstand harsh environments.

Transparent

| Color: | Black, White |

| Price: | $$ |

| Build Time: | 5 Business Days |

| Subtypes : | HDPE Black, HDPE White |

PEEK

PEEK is well-known for its outstanding heat resistance, mechanical strength, and chemical durability. It is widely used in aerospace, automotive, and medical implant applications, where high performance is essential in extreme temperature conditions.

Transparent

| Color: | Beige, Black |

| Price: | $$$ |

| Build Time: | 5 Business Days |

| Subtypes : | PEEK Beige (Natural) and PEEK Black |

Various Surface Finishes Available

Our injection molding post-processing services include trimming, polishing, painting, and coating to enhance the finish, functionality, and durability of your parts.

| Name | Finishing Look | SPI Finish Grades | Surface Roughness Ra (μm) |

|---|---|---|---|

SPI A

SPI A

|

High Gloss | SPI A1, A2, A3 | SPIA1: 0.012 to 0.025; SPIA2: 0.012 to 0.025; SPIA3: 0.05 to 0.10 |

SPI B

SPI B

|

Semi Gloss | SPI B1, B2, B3 | SPI B1: 0.05 to 0.10; SPI B2: 0.10 to 0.15; SPI B3: 0.28 to 0.32 |

SPI C

SPI C

|

Low Gloss | SPI C1, C2, C3 | SPI C1: 0.35 to 0.40; SPI C2: 0.45 to 0.55; SPI C3: 0.63 to 0.70 |

SPI D

SPI D

|

Matte | SPI D1, D2, D3 | SPI D1: 0.80 to 1.00; SPI D2: 1.00 to 2.80; SPI D3: 3.20 to 18.0 |

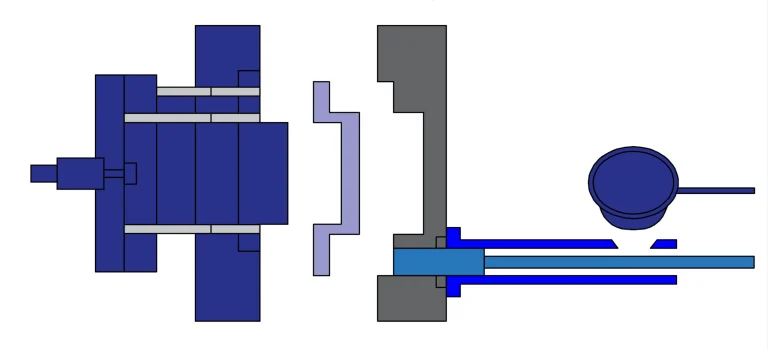

How Future Parts Injection Molding Process Work

Whether you’re looking for prototypes, low-volume runs, or mass production of plastics molded parts, we guarantee fast turnaround times and exceptional quality at every step of the process.

Upload 2D and 3D Drawings

Submit your 3D CAD files and 2D technical drawings via our secure platform.

Get Quote with DFM

You’ll get a quote and manufacturability feedback within 2-3 days.

Review T1 Sample

Receive T1 samples for review in 2–3 weeks before production begins.

Production Begins

Once samples are approved, production begins with a lead time of 3–7 business days.

Delivery

We deliver your custom injection molded parts directly to your doorstep, ready for immediate use.

Ready to Start

Start your injection molding project with Future Parts today and receive your custom parts in just a few days.

Injection Molding Capabilities

| Standards | Description | |

|---|---|---|

| Machine size | 30 to 1,000 tons | |

| Mould tool material | Aluminium and steel (various grades) | |

| Shot life | 500 to 10 w+ shots (MOQ of 1) | |

| Mold type | Single cavity, multi cavity and family molds | |

| Lead time | T1 samples as fast as 2 weeks |

Put Your Parts into Production Today

All information and uploads will be kept confidential.

FAQs about Injection Molding Services

Lead times can range from a few days to several weeks depending on the complexity of the mold and the quantity of parts. First-time samples (T1) can often be delivered in as little as two weeks.

Injection molding offers high production speed, low per-unit cost for large volumes, the ability to create complex shapes with high precision, and minimal waste due to the efficiency of the process.

The MOQ varies by manufacturer but generally starts at 1, especially for prototyping. However, cost efficiency improves with larger orders due to the setup and tooling costs.

Yes, injection molding can produce highly complex shapes with intricate details, undercuts, and thin walls, making it ideal for detailed, high-precision parts.

Thermoplastics can be melted and re-molded multiple times, while thermosets harden permanently after being molded. Thermoplastics are more commonly used in injection molding due to their flexibility and ease of processing.

Resources